The Chemical & Biomolecular Engineering Department would like to congratulate Dr. Radenka Maric on being honored as a 2021 Board of Trustees Distinguished Professor!

The Chemical & Biomolecular Engineering Department would like to congratulate Justin Amengual ’22, Emily Miller ’22, Kaylee Walsh ’22, and Alexander Pericolosi ’23 on being recipients of the Fall 2021 Change Grant as part of the UConn Co-op Legacy Fellowship Program! To view the full list of Fall 2021 Change Grant Recipients, please click here.

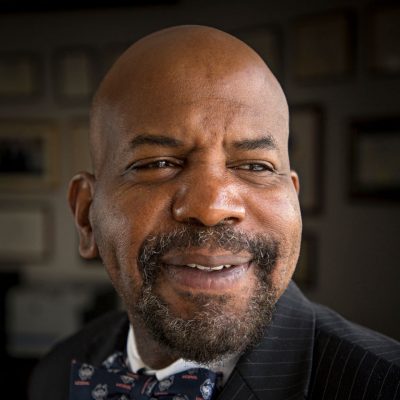

The CBE Department would like to congratulate Dr. Cato Laurencin on being named the 2021 recipient of the Spingarn Medal through the National Association for the Advancement of Colored People (NAACP)! For more information on this award and Dr. Laurencin’s achievements leading up to it, please click here.

The CBE Department would like to congratulate Dr. Cato Laurencin on being named the 2021 recipient of the Spingarn Medal through the National Association for the Advancement of Colored People (NAACP)! For more information on this award and Dr. Laurencin’s achievements leading up to it, please click here.

Congratulations to CBE alumni, Andrea Naranjo-Soledad (’19) and Fernanda Sulantay (’20), on earning NSF Graduate Research Fellowships. For more details, please click here to read the UConn Today article.

Congratulations to undergraduate students Craig Allen, Talha Bhatti, Samuel Degnan-Morgenstern, and Nicholas Skovran for taking 1st place in the Jeopardy competition at the 2021 Eckhardt Northeast Student Regional Conference of the American Institute of Chemical Engineers.

The Chemical and Biomolecular Engineering Department would like to congratulate Professor Anson Ma on receiving this prestigious fellowship. More information regarding this fellowship and how it relates to his research can be found here.

The Chemical & Biomolecular Engineering Department would like to congratulate Professor Anson Ma on being named a 2020 Air Force Research Lab Summer Faculty Fellow. More details regarding this prestigious fellowship can be found here.

The Chemical & Biomolecular Engineering Department would like to congratulate Professor Barry Carter on his selection as an Honorary Fellow of the Royal Microscopy Society. Professor Carter is being recognized for “…outstanding internationally-recognized contributions to microscopy in both science and education over several decades.” Selection as a Fellow is considered the most prestigious honor bestowed by the Society. More details regarding his appointment can be found here.

A new position is now open for tenure track Assistant/Associate Professor at the Chemical and Biomolecular Department. Search # 2020288

The Chemical & Biomolecular Engineering Department at the University of Connecticut invites applications to fill a tenure-track faculty position at the assistant or associate professor level, with an expected start date of August 23, 2020.

The University of Connecticut (UConn) is entering a transformational period of growth supported by the $1.7B Next Generation Connecticut (http://nextgenct.uconn.edu/) and the $1B Bioscience Connecticut (http://biosciencect.uchc.edu/) investments and a bold new Academic Plan: Path to Excellence (http://issuu.com/uconnprovost/docs/academic-plan-single-hi-optimized_1). As part of these initiatives, UConn has hired more than 450 new faculty members at all ranks during the past three years. We are pleased to continue these investments by inviting applications for one Assistant or Associate Professor position in the Chemical & Biomolecular Engineering Department.

The successful candidate will be expected to contribute to research and scholarship through extramural funding (in disciplines where applicable), high quality publications, impact as measured through citations, performances and exhibits (in disciplines where applicable), and national recognition as through honorific awards. In the area of teaching, the successful candidate will share a deep commitment to effective instruction at the undergraduate and graduate levels, development of innovative courses and mentoring of students in research, outreach and professional development. Successful candidates will also be expected to broaden participation among members of under-represented groups; demonstrate through their research, teaching, and/or public engagement the richness of diversity in the learning experience; integrate multicultural experiences into instructional methods and research tools; and provide leadership in developing pedagogical techniques designed to meet the needs of diverse learning styles and intellectual interests.

The research specialty of primary interest is in the area of energy broadly interpreted, with research interests including, but not limited to: advanced energy materials, processes, and systems; combustion science & technology; energy storage and power management; fuels and fuel processing; renewable energy & resources; or bioenergy/biofuels. Other topics in the broad area of energy are also welcome.

DUTIES AND RESPONSIBILITIES

Minimum Qualifications: Candidates must have an earned Ph.D. in Chemical Engineering or a related field by the time of appointment; an established record of research with demonstrated potential for excellence in teaching commensurate with experience; and a commitment to promoting diversity through their academic and research programs. Candidates must also demonstrate a commitment to graduate education.

Preferred Qualifications: Preferred candidates will possess an outstanding record of scholarship and research contributions commensurate with experience, with accomplishments that demonstrate the relevance of their research to the chemical engineering and/or energy field in general. A record of excellence in teaching; the ability to effectively communicate with students in both large and small audiences, and a record of public engagement are equally desirable.

This is a full-time, 9-month, tenure track position with an anticipated start date of August 23, 2020. The successful candidate’s primary academic appointment will be at the Storrs campus. Salary will be commensurate with qualifications and experience.

This position will be filled subject to budgetary approval.

To apply, click here and select “Apply” to be redirected to Academic Jobs Online to complete your application. Please submit the following: a cover letter, curriculum vitae, research and scholarship statement; teaching statement (including teaching philosophy, teaching experience, commitment to effective learning, concepts for new course development, etc.); commitment to diversity statement (including broadening participation, integrating multicultural experiences in instruction and research and pedagogical techniques to meet the needs of diverse learning styles, etc.); and sample articles or books. Additionally, please follow the instructions in Academic Jobs Online to direct three reference writers to submit letters of reference on your behalf. Screening of applicants will begin immediately and continue until the position is filled. Employment of the successful candidates will be contingent upon the successful completion of a pre-employment criminal background check. (Search # 493703)

UCONN Biodiesel technology led by Prof. Richard Parnas was installed at the wastewater treatment plant of the city of Danbury in CT. “We will be converting their waste stream, brown grease, to biodiesel fuel for use in their municipal vehicles, school buses, and heating systems” said Prof Parnas. A proposal was submitted to the city of New Haven to install the same technology to their water treatment facility. New Haven and Danbury are very excited to include UCONN as a partner in these projects.

Around the world, fresh water scarcity poses a major economic, environmental, and humanitarian challenges. The U.S. Department of Energy (DOE) and other federal agencies have forged important collaborations with universities, the private sector, the National Labs, and other organization to find innovative and practical solutions to address this threat.

Around the world, fresh water scarcity poses a major economic, environmental, and humanitarian challenges. The U.S. Department of Energy (DOE) and other federal agencies have forged important collaborations with universities, the private sector, the National Labs, and other organization to find innovative and practical solutions to address this threat.

U.S. Secretary of Energy Rick Perry announced Monday that the National Alliance for Water Innovation (NAWI), a research consortium including the University of Connecticut, has been awarded a five-year, $100-million Energy-Water Desalination Hub (pending appropriations) to address water security issues in the United States. The hub will focus on early-stage research and development for energy-efficient and cost-competitive desalination technologies and for treating nontraditional water sources for various end uses.

Jeffrey McCutcheon, Al Geib Professor of Environmental Engineering Research and Education in UConn’s School of Engineering, is leading UConn’s participation in NAWI. McCutcheon is an internationally recognized expert in membrane technologies for sustainable water and energy production. He serves as a deputy thrust area lead for the hub’s R&D activities involving materials and manufacturing, and is also the UConn site representative to NAWI.

“UConn is excited to join a team consisting of top researchers in the field of water treatment and desalination,” says McCutcheon, who is also executive director of the Fraunhofer USA Center for Energy Innovation at UConn Tech Park. “While Connecticut does not suffer from severe water shortages, we do have water quality challenges that could see solutions emerge from this effort.”

McCutcheon anticipates that NAWI will tap into UConn’s expertise in areas like membrane technology, waste water treatment, computational development, and systems design, to create a stable and resilient water supply for agriculture, industry, and communities. NAWI hopes to achieve these goals through a “circular water economy,” by which water is treated for a specific purpose and reused at the local level rather than being transported long distances.

As a DOE Energy Innovation Hub, NAWI will not only conduct research but also develop a roadmap to prioritize the highest impact technology options, then identify and solicit projects to support those priorities.

NAWI’s goal is to advance a portfolio of novel technologies that will secure a circular water economy in which 90% of nontraditional water sources – such as seawater, brackish water, and produced waters – can be cost-competitive with existing water sources within 10 years.

According to McCutcheon, many of UConn’s research strengths align well with NAWI’s goals.

“Not only is UConn home to one of the highest quality material characterization facilities in the country, many UConn faculty members also already contribute to important water safety initiatives like Governor Lamont’s task force on hazardous chemicals in the Farmington River,” says McCutcheon. “I’m confident that UConn’s preeminent researchers and high-tech infrastructure will allow us to play a significant role in the NAWI innovation hub.”

Consider the complexity of a modern passenger airliner. An aircraft is a self-contained “system-of-systems,” consisting of a diverse assortment of interdependent subsystems and components working together. Electrical, hydraulic, flight control, fuel handling, cabin pressurization, and engine systems are all crucial parts of a functional aircraft, each with their own constraints and requirements in addition to those of the aircraft as a whole.

Consider the complexity of a modern passenger airliner. An aircraft is a self-contained “system-of-systems,” consisting of a diverse assortment of interdependent subsystems and components working together. Electrical, hydraulic, flight control, fuel handling, cabin pressurization, and engine systems are all crucial parts of a functional aircraft, each with their own constraints and requirements in addition to those of the aircraft as a whole.

The complexity of engineering interconnected systems like aircrafts — or, for that matter, power plants, smart buildings, and modern manufacturing facilities — has led many industries to migrate toward formalized systems engineering, considering large systems holistically.

Led by George Bollas, the United Technologies Corporation Institute for Advanced Systems Engineering (UTC-IASE) has been solving these real-world problems for industry since 2013.

Bollas, who is a professor of chemical and biomolecular engineering in UConn’s School of Engineering, focuses his research on process design, simulation, optimization, control, and diagnostics. These research interests align seamlessly with the needs of industry partners like United Technologies Corporation.

Located in the University of Connecticut Tech Park’s Innovation Partnership Building, UTC-IASE is working on some of the most pressing challenges for businesses and research sponsors using innovative approaches to model-based systems engineering.

“We have converted it to something that is self-sustained and can work with United Technologies at many levels, but also engage other satellite industry partners, the state, and federal agencies to have a greater impact,” says Bollas.

Location, Location, Location

At UConn Tech Park, students from different departments and research groups in the School of Engineering who are working on different projects managed by the UTC-IASE can come together in a central location. Much like the complex operations the students are researching, their individual projects and skills all work together to make systems more efficient. Bollas says this allows for close collaboration and frequent discussion of what each individual group is tackling.

“For the first time we’re all in one place,” Bollas says. “To develop that culture for students, where they work next to each other, day and night, and all that good competition that comes out of it is very positive for the mindset and culture both at UConn and when these students go out in the workforce.”

“Industry often focuses on measurable outcomes, seeking means for producing their products better, faster, and at reduced cost. Awareness of these tangible impacts helps students understand the importance of their research”, says Bollas.

“In many cases, you know from the get-go that you are going to help a company solve a $10 million-a-year problem. It’s very exciting for the students to work on something that they understand has immediate value and impact on such a huge scale,” Bollas says.

Many of the students at the UTC-IASE go into careers with United Technology Corporation or other companies in the area of manufacturing, energy, aerospace, building, and robotics. The experience contributes to the preparation of graduate and undergraduate students for these careers as they learn to communicate with industry partners effectively and consistently.

“It’s a natural next step,” Bollas says. “It’s very helpful to know where they might be going, what they’re going to face in industry or academia.”

In addition to graduate research, UTC-IASE exposes UConn students to business professionals through a training program that was originally designed for employees of the corporation. Bollas says this training is critical, since the entire concept of systems engineering works to un-train students from thinking about problems in terms of their own specificity.

“In both research and training, we emphasize the concept of system-level thinking. One needs to understand what the entire system looks like – from architecture to requirements, design, commissioning, performance, and maintenance. This approach relies on thinking of the entire life-cycle of a system from design to decommissioning.”

To accomplish this, UTC-IASE offers training of professionals through a formal Graduate Certificate and a Master of Engineering program in Advanced Systems Engineering. These programs are offered to geographically dispersed professionals as well as students at UConn who are interested in developing a unique and valuable set of skills in the areas of model-based systems engineering of cyber-physical systems.

“We’re helping lifelong learning for the existing engineering workforce,” Bollas says. “We’re helping them understand what is the state-of-the-art, and some of the approaches and solutions to the problems they are dealing with in their everyday work. We call this integration of undergraduates, graduate students, and professional engineers a ‘talent eco-system’ that can produce and sustain a modern engineering workforce in the state and for the nation.”

Big Problems, Real Solutions

Bollas is currently collaborating with Collins Aerospace to improve fault detection and isolation methods. The advanced detection algorithms Bollas and his research team are developing are optimized for actively identifying faults during aircraft operation and helping to reduce false alarms. This project has already led to two patent applications filed jointly by UConn and Collins Aerospace.

“We’re transferring what we develop here at the university to actual industry environments, where we have access to all the data, constraints, requirements, and system-specific details. We do this through internships and sabbatical leaves, and this has really been a wonderful model for technology transfer,” Bollas says. “I’m not sure we’d be aware of the significance and limitations of our research if we weren’t working with a technology leader like UTC.”

Bollas again points to the importance of location, both in Connecticut and at Tech Park, to help the institute grow.

“There are so many opportunities generated for the institute just because we are located here,” Bollas says. “We’re working with several other Tech Park centers and their industry partners since they are more and more focused on ‘smart’ processes for manufacturing.”

Bollas is referring to a paradigm shift dubbed Industry 4.0 or “smart manufacturing,” which places emphasis on cyber-physical systems. Cyber-physical systems include physical machines controlled by computer-based algorithms that are deeply ingrained in the so-called Internet of Things. To remain competitive, companies like Collins Aerospace and Pratt & Whitney have been investing in the development of smart manufacturing technologies in their respective industries.

By having access to test beds at the Connecticut Center for Advanced Technology and the Pratt & Whitney Additive Manufacturing Center in the IPB, the UTC-IASE researchers working on smart manufacturing projects with the Department of Energy provide a better picture of how well their research, algorithms, and solutions will work when used in an industrial setting.

“Smart manufacturing solutions are sometimes easy on a computer, but when you actually have to deploy these advanced technologies, it’s very helpful to have test beds we can use right here at the Tech Park,” Bollas says.

Bollas says he is proud of laying a strong foundation for future growth through partnerships with industry and federal agencies on such a large scale. Moving forward, he has no doubt that the research collaborations taking place at UTC-IASE will continue to generate innovative, real-world solutions that help Connecticut and its industry partners grow.

– Anna Zarra Aldrich ’20 (CLAS), Office of the Vice President for Research

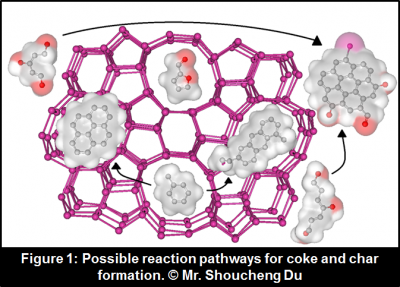

Julia Valla, Assistant Professor at the Chemical and Biomolecular Environmental Department of the University of Connecticut received a CAREER Award from the National Science Foundation to research the removal of sulfur molecules from transportation fuels. The award for $500,000 will revolutionize sulfur removal using adsorption in ion exchanged zeolites.

Valla began working on sulfur removal as a Ph.D student. By the end of the five years of her CAREER project, Valla aims to develop novel filters that can efficiently and economically remove the sulfur molecules from fuels.

“The CAREER award was very important for me because I can continue research what I started 18 years ago. It is important that I can evolve on findings that I have already created,” Valla said.

She explained that sulfur molecules found in transportation fuel are toxic. They have adverse effects on the environment and subsequently on humans. Sulfur oxides which can be emitted from cars can cause acid rain, which causes environmental pollution.

“The reason why I keep pushing this effort is because the sulfur molecules, this impurity has very detrimental effects on the environment and consequently on humans, and on our lives,” Valla said, “The fossil fuels, whether we like it or not, is still our main source of energy. We do need to, of course, be looking to renewable energy resources and put our efforts into research on renewable energy. However, it’s also important to do something about the fossil fuels that we use now.”

Currently, sulfur is removed from fuels in a process called hydrodesulfurization in the refinery. Valla said the process requires severe conditions and the use of hydrogen makes it an expensive process. Her research will focus on utilizing ion-exchanged zeolites, specifically zeolite Y, which is a porous mineral. The zeolites will be tested for their selectivity in binding to sulfur and not to other molecules in the fuel, and how well they adsorb the sulfur to reach the mandatory government standards.

The zeolites can be regenerated and reused, which makes them a more affordable alternative to hydrodesulfurization.

“The major challenge is to create a sorbent that has high selectivity in sulfur molecules, meaning that it will adsorb the sulfur molecules, leaving the other molecules in the fuel intact, ” Valla said.

This project will be an iterative process that uses experiments and models to “create fundamental knowledge on how the properties of metals and bimetals-exchanged Y zeolites, such as pore size, metals properties, location, oxidation state and interaction, affect the adsorption process.”

Valla will be working to optimize a zeolite so that it can be extremely selective in finding sulfur molecules and then adsorb them.

She explained that this research can lead to a product that can have significant impact on the environment and consequently humans.

“As the regulations become more strict, the refineries need to use more severe and expensive conditions in the hydrodesulfurization process, so if we find something now that’s more economical and visible that will save us a lot of lives, and environmental problems,” Valla said.

Written by: By Sarah Al-Arshani

Photography by: Thomas Hurlbut

In an effort to support the doctoral training of graduate students in the Polymer Program of the Institute of Material Science, a proposal by Kelly Burke, Assistant Professor of Chemical and Biomolecular Engineering, was recently awarded funding under the Graduate Assistance in Areas of National Need (GAANN) from the United States Department of Education.

In an effort to support the doctoral training of graduate students in the Polymer Program of the Institute of Material Science, a proposal by Kelly Burke, Assistant Professor of Chemical and Biomolecular Engineering, was recently awarded funding under the Graduate Assistance in Areas of National Need (GAANN) from the United States Department of Education.

Burke, a member of the Polymer Program, said that the proposal, which is focused on bio-derived and bio-inspired polymers, is meant to support graduate students as they complete their doctoral coursework and research. The funding permits the recruitment and support of a larger and more diverse cohort of STEM students, with particular focus in growing participation from females and other groups traditionally underrepresented in science and engineering.

“Really the goal is to provide financial support in the form of tuition, fees, and fellowship stipends for graduate students,” Burke said. “What that means is that we can grow our graduate program. We can support more students, train more students.”

She said that admitting and training a diverse group of students is important for better representation of our communities as well as for the generating of ideas from teams of people with different perspectives.

“We want to provide more opportunity for students to earn graduate degrees. This award allows us to provide high-level technical training to our candidates to position them to be leaders and innovators in the field,” Burke said. “Our program aims to equip students with the research and communication skills that they need so they can go out and make the mark that they want to have on the world. This award also allows us to recruit and support qualified people who may not have previously considered graduate school.”

The theme of the research is focused on creating materials that are “bio-derived” or “bio-inspired” meaning they originate from or are inspired by nature.

“Nature is the best at doing pretty much everything, including making polymers,” Burke said.

The Polymer Program as well as this proposal is multi-disciplinary, combining professors and students from the Chemical and Biomolecular Engineering, Biomedical Engineering, Physics, and Chemistry Departments. Burke said this proposal allows for great collaboration between members of the various departments.

The proposal supports 12 different projects that focus on mimicking natural materials to overcome some of the limitations of conventional plastics.

Burke explained that a wide range of materials can actually be considered polymers. The projects mainly deal with creating different materials that can interact with various type of surfaces.

“Our materials are polymers, which are very big molecules. When people think of polymers, they often think about plastics that they encounter daily. Polymers are also things like rubber bands and gels. They can be hard or soft, and they can act like liquids, solids, or in between. There really is a wide variety of materials that are polymers,” Burke said.

She herself will be working with a biopolymer, silk protein, in hopes of developing a material that can be used on the surface of the intestine to help with symptoms of inflammatory bowel diseases. Burke explained that, in some cases, inflammation is caused when the mucus within the intestine erodes and bacteria enters a wound in the wall of the intestine.

Burke is interested in designing and chemically modifying silk proteins so that they can be injected into the intestine as a liquid and then form a gel layer to stick to the inside of the organ.

“You can think about that gel layer just as a physical barrier to help if the mucus is eroded, but it also has a way to deliver treatment locally. A lot of inflammatory bowel diseases have what we call systemic treatments. You have either a pill or injection that treats the symptoms of the disease but that can have some serious side effects,” Burke said.” So, what we’re trying to do is design polymers that can interact at the site of inflammation and that are a localized delivery depot for therapeutics.”

For Burke this is a part of a larger interest in looking at how materials can interact with cells.

“I’m really interested in influencing cells to function in different ways just using materials. For example, often scientists need to be able to transition adult stem cells into different types of cells, like bone cells, fat cells, or nerve cells. They do this to understand how cells function when they are healthy and diseased. The most common way to do this now would be to deliver chemicals to cause the cells to differentiate and behave in a specific way,” Burke said. “One challenge with transitioning a technology or treatment from the lab into a clinical setting is that there can be undesired consequences when reagents diffuse out and travel to different places in the body.”

Essentially this would be a project looking at the possibility of promoting healing in intestinal tissue by delivering a localized treatment for inflammation with a material rather than delivering a potent treatment systemically.

“My lab has been very interested in trying to use the properties of a material to affect cellular behavior,” Burke said. “If you can control how cells and tissues function using materials, you may be able to reduce the need to deliver very potent biological molecules. This would open up many new possibilities in regenerative medicine and engineering.”

While this is only one project of the many proposed under the grant, all the projects focus on utilizing polymers derived or inspired by natural materials. Some projects focus on material synthesis, while others focus on complex characterization techniques and building computer models to predict their behavior. Many of the projects seek to understand and control the interaction of materials with various surfaces for tangible applications.

Article by Sarah Al-Arshani

Photography by Thomas Hurlbut

Nikolas Franceschi-Hoffmann, Geyser Remediation LLC.

Currently people in the drinking water industry are beginning to realize that a family of contaminants that had previously slipped under the radar, Per-and Poly-Fluoroalkyl Substances (PFASs), are almost certainly toxic, and cause a variety of issues from developmental to cancers. Environmental regulators have therefore begun to regulate PFASs in some states as a result. However, no good technologies exist on the market that can get rid of all the chemicals in the family effectively, or cost-efficiently. Through work that started as a senior design project, we think we have designed a reactor capable of doing just that. If we can prototype it to prove that, then there is a good chance we can push regulators in states currently without regulation over the edge to start regulating in their state, too. That would effectively create a hostage market for us, as water utilities would be forced into compliance. We currently do not yet have a patent, but are working with the UConn IP Law Clinic to get a provisional patent. Indicators in the market are good for us as one estimate suggests as much as 1/3rd of the US population, or 110 million people are affected by this problem. Additionally, our end customers: water utilities and government agencies that we have met with thus far are all very interested and have shown excitement at the prospect of having a potential solution on the way.

Kristina Wagstrom, Eversource Energy Assistant Professor of Environmental Engineering Education at the University of Connecticut, received a CAREER Award from the National Science Foundation for a project that will evaluate air pollution in various neighborhoods in Hartford.

Kristina Wagstrom, Eversource Energy Assistant Professor of Environmental Engineering Education at the University of Connecticut, received a CAREER Award from the National Science Foundation for a project that will evaluate air pollution in various neighborhoods in Hartford.

The five year, $500,000 project entitled “Engaging Communities to Bridge the Local to Regional Gap in Air Pollution Exposure Assessment” began in June 2018. Wagstrom and students in one of her service learning elective courses will be working with various neighborhoods in Hartford to tackle issues of near road air pollution. They will develop recommendations for individuals, communities, and policy changes to mitigate the impact of air pollution.

“The motivation behind this project is to provide ways to better understand real world air pollution exposures and take into account near road exposures,” She said.

One part of the project will involve monitoring air pollution in Hartford using low cost equipment. Wagstrom said that for every year of the project researchers will partner with different neighborhood associations in Hartford to do modelling and monitoring of air pollution in that neighborhood. Citizen will able to set up some monitors themselves as well.

Wagstrom said the project will focus on using a hybrid modeling approach that will yield better estimates of air pollutant concentrations than other models.

“A lot of the actual effort on the project is developing this complex new model,” Wagstrom said “The goal is to provide a tool that can be used anywhere to provide better air pollution estimates that can then be used to make recommendations to people about how they might want to change their own activity and make recommendations to communities and city planners about better ways of planning urban areas.”

She said the new modeling system will allow them to better estimate, for example, the difference between walking or biking down one road versus another during different times of day.

“So really giving us much better estimates to what your air pollution exposure would look like given different activity patterns. Different ways of going about your life day to day,” Wagstrom said.

Article by Sarah Al-Arshani

Photography by Peter Morenus

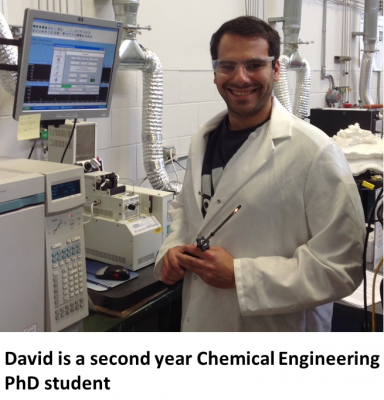

Dr. Xiaoguang Peng – a postdoctoral research associate from Dr. Anson Ma’s research group – has received a prestigious fellowship from Anton Paar in recognition of his expertise in rheology and contributions to the science of complex fluids. Dr. Peng received his PhD degree in Chemical Engineering from Texas Tech University in 2016. Before joining UCONN in 2018, he was a PhD student and then a postdoctoral fellow in Prof. Greg McKenna’s group at Texas Tech. He has over 10 years of experience in the synthesis and characterization of polymers and colloidal dispersions.

The Anton Paar fellowship was established in 2016 as part of a strategic partnership between Ma’s research group and Anton Paar – a world-leading manufacturer of measurement instruments. The company has provided fellowships and loaned their most advanced rheometer, the MCR 702 TwinDrive Rheometer, to Dr. Ma’s lab. https://news.engr.uconn.edu/new-partnership-brings-high-end-research-equipment-to-uconn.php

(Photo by: Thomas Hurlbut)

Congratulations to Professor Valla on receiving the NSF grant! More details may be found via the following link. (Article by Anna Zarra Aldrich)

The Chemical and Biomolecular Engineering Department welcomes Liang Zhang as an Assistant-Professor.

Dr. Zhang’s research focuses on developing theoretical frameworks and computational methods to accelerate the discovery of materials. In particular, he is interested in catalytic materials and other functional materials that enable efficient chemical transformation and energy storage.

Dr. Liang Zhang earned his Ph.D. degree in Physical Chemistry from the University of Texas at Austin in 2015. After that, he worked at Stanford University and the University of Pennsylvania for his postdoctoral training. The primary area of Dr. Zhang’s research is to use state-of-the-art computational tools to simulate and understand chemical reactions from first principles. His research aims to the in-silico discovery and engineering of materials for energy and environmental applications.

Professor Yu Lei, Chemical and Biomelcular Engineering, has been chosen for appointment to a Centennial Term Professorship in the School of Engineering. The Centennial Term Professorships, established through an anonymous donation of $1 million, are aimed at recognizing outstanding faculty members who have left a lasting impact on the School of Engineering through leadership and innovation in teaching, research, mentorship, engagement, and institution building.

Dr. Lei received his Ph.D. in 2004 from the University of California-Riverside. He joined UConn’s Chemical and Biomolecular Engineering in 2006. Dr. Lei is a well-acknowledged expert in the areas of chemical and biological sensors. The primary area of Professor Lei’s research is to develop novel, simple, cost-effective, ultrasensitive, and universal (bio)sensor and/or nanomaterial-based sensor platforms for the detection of biological and chemical species, which combine the principles of chemical engineering, nanotechnology and molecular biology for homeland security, environmental, energy and biomedical monitoring.

Dr. Lei is an elected Fellow of American Institute of Medical and Biological Engineering (AIMBE) and an elected member of the Connecticut Academy of Science and Engineering (CASE). He is a licensed Professional Engineer (P.E.) in Chemical Engineering and was a recipient of UConn School of Engineering Dean’s Excellence Award in 2016. Dr. Lei has over 140 peer-reviewed journal publications, 3 invited book chapters, and more than 10 patents/disclosures.

Richard Parnas of the IMS Polymer Program enjoyed a visit from Governor Danell Malloy to the site of UConn’s collaborative project with the Greater New Haven Water Pollution Control Authority and REA Resource Recovery Systems LLC on September 27, 2018. The visit celebrated the first milestone of the project, where the brown grease waste stream from the East Shore wastewater treatment plant is converted to biodiesel fuel in a process patented by Dr. Parnas that REA licenses from UConn. Dr. Parnas and REA installed a mini-refinery at the East Shore treatment plant with capability to produce approximately 400,000 liters per year of biodiesel fuel from the brown grease. That system serves as a 1/10 scale demonstration of a typical commercial system the company can install at many of the thousands of wastewater treatment plants throughout the world. For ease of installation, the entire demonstration system was constructed inside of 2 CONEX shipping containers at ProFlow, Inc. of North Haven, CT. Future plans include the installation of a turbo-electric generator to demonstrate a pathway to converting the waste stream to power at a cost much less then required with current biodigester technology.

Cong Liu, a chemical engineering graduate student working with Prof. Parnas, describes aspects of the conversion process to an aide to Governor Malloy while standing outside of the main reactor room of the mini-refinery.

Governor Malloy, Dr. Parnas, and UCONN Chemistry undergraduate Dylan Ramirez discuss the importance of waste management and power generation to the wastewater treatment industry.

REA managing partner Al Barbarotta, Governor Malloy and Prof. Parnas discussing the chemistry of the conversion process while standing in the main reactor room of the mini-refinery. A cluster of 3 continuous stirred tank reactors, a multi-phase laminar flow reactor, and a liquid/liquid extractor are visible in the background.

Congratulations to Professor Yu Lei and Professor Ranjan Srivastava for their induction into the Connecticut Academy of Science and Engineering. More details may be found via the following link.

By: Taylor Caron

Professor Yu Lei has been inducted into the American Institute of Medical and Biological Engineering for his work in biological sensor design and testing. AIMBE is a one of the most prestigious institutes for medical and biomedical engineers as it comprises of only the top 2% of professionals in the field. While he is proud of his achievements, he said he has no intention of resting on his laurels. His research is heading toward a focus on digital technology which would make biosensors more affordable for individuals.

Lei spoke of the nature of his work that AIMBE is recognizing: “AIMBE considers professionals whose accomplishments are related to medical issues. It has always been my desire to work toward innovating more effective and affordable tools for medical professionals which is why this is so rewarding,” he said.

Lei has been credited with adapting the traditional area of electrochemistry for nanoscale structures for not only sensing, but also for applications in biocatalysis and chemical catalysis. The institute recognizes him as the pioneer in developing nanostructured metal oxide based enzymatic and non-enzymatic glucose biosensors with strong success in combating diabetes. AIMBE has seen these achievements, among others, as seminal advancements in public health.

He spoke about the process of induction which includes nomination, rigorous screen testing, and voting by the College of Fellows. He said there must be an affirmative vote of at least 74.5% in order to be inducted.

“It was certainly surprising to know that so many of AIMBE’s incredibly prestigious College affirmed my induction, but also was an excellent feeling that all this hard work paid off,” he said.

According to Lei, a professional network of AIMBE’s stature can significantly promote and advance a researcher and their university. He said that UConn is increasingly becoming a more recognized and accolated research university, and that being able to represent the Chemical Engineering and Biomolecular Department at AIMBE will only further highlight the program on a national level.

Lei said that networking opportunities with AIMBE can aid with research projects going forward. As previously mentioned, Lei believes the future of biosensors, a field in which he already is seen as a pioneer, needs to look to digital technology. A digital biosensor will not only be more affordable than electrochemical biosensors, but also can be more precise in detecting targeted molecules.

“We are looking to develop a biosensor which can detect a small molecule, allowing for medical professionals to detect and track dangerous or toxic molecules early on. This is the kind of technology which is available in some hospitals, but it is very large and expensive equipment. This technology needs to be available for individuals so they can communicate with their doctors regularly about the concentration level of toxic molecules or biomarkers for diseases,” Lei said.

Though Lei cannot disclose too much about the specificities of his current research, he was happy to comment that there have been reassuring successes. He mentioned that even the current biosensors used in hospitals can error in their use of the universal standard, and that a more personalized system is necessary.

“So different people have different thresholds regarding biomarker concentration. What is dangerous for me might not necessarily be dangerous for someone else and vice versa. What we’re looking for is home-use, so that different persons can track their own individual molecule concentration. If there’s a sudden spike one day, they can contact their doctor earlier rather than later.”

Lei’s research group consists of undergraduate and graduate students who work closely with the professor on this relatively new area of research. Lei admits that he has high expectations for his students, but it is because he believes in the power of this technology for the public health and beyond.

“Yes, sometimes I push them hard but I selected them because I know they are capable of pursuing this research with me. These kinds of biosensors could also have significant applications in environmental work. This is what excites me: I think it’s important to always be pushing forward, always looking to the future for new opportunities,” he said.

By: SoE News (http://news.engr.uconn.edu/professor-cato-t-laurencin-to-receive-2016-connecticut-medal-of-technology.php)

Dr. Cato T. Laurencin, a world-renowned physician-scientist in orthopaedic surgery, engineering, and materials science, has been named the 2016 recipient of the Connecticut Medal of Technology. Laurencin, of the University of Connecticut will accept the award at the 41st Annual Meeting & Dinner of the Connecticut Academy of Science and Engineering (CASE) on May 24.

Laurencin, a CASE member since 2009, is a pioneer who has developed technologies that are revolutionary and that are in use in important applications in the marketplace. He has exhibited leadership and courage in the development of new initiatives for science and entrepreneurship.

Laurencin is a University Professor at UConn. He is the 8th University Professor in the school’s history. This rare title is awarded to individuals for extraordinary academic excellence, and sustained, high-level achievements in administration at the school and is UConn’s highest faculty distinction. He currently is chief executive officer of the Connecticut Institute for Clinical and Translational Science, where he leads the university’s translational science research infrastructure. He is the founding director of the Institute for Regenerative Engineering and the Raymond and Beverly Sackler Center for Biomedical, Biological, Physical, and Engineering Sciences at UConn Health. In addition, he is a professor across the university, as well as a board certified orthopaedic surgeon, endowed professor of orthopaedic surgery, and fellow of the American Academy of Orthopaedic Surgeons, the American Institute of Chemical Engineers, the Biomedical Engineering Society, the Materials Research Society, and the American Chemical Society.

Laurencin has achieved not only a breadth of experience across multiple fields, but also a depth of accomplishments that places him at the highest echelon of each area in which he has been involved.

He is the scientific founder of Soft Tissue Regeneration (STR), a Connecticut company. STR is commercializing breakthrough technologies for anterior cruciate ligament regeneration (knee) and rotator cuff regeneration (shoulder). The shoulder rotator cuff regeneration device has been cleared for use by the FDA, and the anterior cruciate ligament device is now in clinical trials in Europe. In addition to STR, Laurencin is scientific co-founder of Natural Polymer Devices (NPD). NPD is a Connecticut company that focuses on developing polysaccharide polymer technologies for bone regeneration. The company is in the process of seeking FDA clearance of a novel fracture repair device for the treatment of cervical spine fractures.

Laurencin was named one of the 100 Engineers of the Modern Era by the American Institute of Chemical Engineers at their Centennial Celebration in 2009. He was named for his seminal work in the development of polymerceramic systems for bone repair. In seminal papers and patents, he described the development of composite matrix systems that could foster bone healing. That research, which has continued to this day, has been the inspiration for the biocomposite interference screw, a principal means of fixation bone. Laurencin’s work in the development of sintered polymer microspheres for bone repair has inspired products now on the market. His research has also focused on the development of degradable polymers for drug delivery applications based on the polyanhydrides. Work in that area resulted in the development of products for bone infection treatment and brain tumor treatment.

Laurencin has shown leadership nationally and in Connecticut in the fostering of new technology. He served as a permanent member of the orthopaedic device panel for the U.S. Food and Drug Administration. Later he was appointed by the Secretary of Health and Human Services to the National Science Advisory Board (Science Board) of the FDA, the overseeing body of that agency. There he helped revamp the FDA and its mission of providing scientifically based decisions on the approval of devices, drugs, and biologics.

In Connecticut, Laurencin has performed distinguished service of the highest order. He was the faculty leader in the development of the state’s Bioscience Connecticut Initiative. This initiative calls for doubling incubator space for new companies at UConn, while otherwise fostering a collaborative environment that encourages inventorship and innovation. Much of the success in the passage of Bioscience Connecticut, especially in educating individuals on the benefits of the initiative, has been attributed to Laurencin.

“The State of Connecticut is proud to award the Connecticut Medal of Technology to Dr. Cato T. Laurencin for his internationally recognized work developing revolutionary technologies using his combined background in medicine and engineering,” said Governor Dannel P. Malloy. “In addition, we honor Dr. Laurencin’s success both as an inventor and as someone who creates environments that allow innovation to grow.”

Laurencin is recognized regionally, nationally and internationally for his work in developing new technologies. In Connecticut, Laurencin was named the 2014 CURE Connecticut Academic Entrepreneur of the Year. He received the Technology Innovation and Development Award from the Society for Biomaterials, their highest award for inventorship, and in 2013 was inducted into the National Academy of Inventors.

Laurencin is an elected member of both the National Academy of Medicine and the National Academy of Engineering, the first orthopaedic surgeon in history to achieve dual election. Internationally, he is a fellow of the Indian National Academy of Sciences, a foreign fellow of the Chinese Academy of Engineering, an associate fellow of the African Academy of Sciences, and a fellow of The World Academy of Sciences. He was named a recipient of the National Medal of Technology & Innovation in December 2015.

Published: April 15, 2016

By: SoE News (http://news.engr.uconn.edu/remembering-dr-michael-howard.php)

Dr. G. Michael Howard, 81, professor emeritus of chemical engineering and beloved husband for 57 years of Jane Deans Howard, passed away on December 21, 2016. Professor Howard served as associate dean for UConn Engineering, as well as department head of chemical engineering during his 36 year tenure as a full time professor. Born in Washington, DC on July 4, 1935, he graduated from the University of Rochester in 1957. He subsequently earned his master’s degree from Yale before coming to UConn to receive his Ph.D.

In 1961 he began his 50 year affiliation with the chemical engineering department at UConn, which is now called the chemical and biomolecular engineering department. Throughout Dr. Howard’s time at UConn he was a favorite of his students and well-respected by his peers. He received numerous teaching honors and awards, including the Outstanding Teacher Award from the Student Government, two-time winner of the Rogers Corp. Outstanding Teacher Award in Chemical Engineering, induction into the UConn School of Engineering Academy of Distinguished Engineers, and the Mike Howard Educational Excellence Fund in Chemical Engineering was established by his peers and former students upon his retirement.

Nationally, Dr. Howard chaired the American Institute of Chemical Engineers (AIChE) National Program Committee on Education and the Liaison Committee between AIChE and the ASEE Chemical Engineering Division.

While at the University of Rochester, Mike was a crafty undersized center on the basketball team and was coached by Louis Alexander, a former UConn player and coach. Mike was also the captain and number one player on the tennis team. For more than 30 years he was a regular at the lunchtime pick-up basketball games in Guyer Gym on the UConn campus. Mike was a devoted UConn sports fan, particularly of the men’s and women’s basketball and soccer teams, and the football team. He enjoyed serving UConn through various positions on athletic advisory committees.

In 2011 Mike was honored with induction into the Hastings High School Hall of Excellence for his contributions to higher education. Two Nobel Prize winners are in the same Hall of Excellence, and in his induction speech, Mike proudly and humbly shared his belief that if you couldn’t win a Nobel Prize yourself, you could still make a wonderful contribution by striving to lay the groundwork for someone else to win one.

Mike was committed to his family and students, making sure that all knew through his support and generosity that he was there to help them reach their highest potential. He was a lover of crossword and number puzzles of all kinds, had endless knowledge of many subjects, loved trivia games and quizzes, and was known to enjoy a good pun.

Mike is survived by Jane, and his three children, Russell Howard and his wife Christina of Williamstown, MA, James Howard and his wife Kateri of Glastonbury, CT, and Ann Howard Phillips and her husband Todd of Wexford, PA. He also leaves his sister, Helen Howard Harmon of San Francisco, CA, brother and sister-in-law William and Nancy Deans of Acton, ME, eight cherished grandchildren, two nieces and one nephew. His family will deeply miss his wisdom, sense of humor, wit and generosity, particularly at the family gatherings on Candlewood Lake.

Memorial contributions can be made to the Mike Howard Educational Excellence Fund by contributing to the UConn Foundation, Inc. 2390 Alumni Drive Unit 3206, Storrs Ct 06269, and referencing the Mike Howard Educational Excellence Fund #22084.

Published: January 12, 2017

By: Taylor Caron

Professor Yongku Cho of the Chemical and Biomolecular Engineering Department has received a Best of BIOT (biochemical technology) award for his presentation at the American Chemical Society’s 2016 National Meeting.

His presentation was entitled “Engineering Antibody Specificity Through Multi-Dimensional High-Throughput Screens,” and is related to his research on creating a more effective antibody to potentially detect Alzheimer’s disease for which he has received a grant from the National Institute of Health (NIH).

Professor Cho’s work involves developing an antibody which will be more effective at binding to the desired target. More precisely, Professor Cho and his lab are developing an antibody which will be more specific in targeting a particular modification that occurs on the target protein known as the Tau protein. He said that his presentation at ACS was focused on their new technology that enables the precise measurement of the antibody’s ability to specifically bind to the desire target.

“The BIOT Award had to do with describing the technology of quantifying antibody specificity,” he said. “Many researchers have focused on what is called affinity, which has to do with an antibody’s strength of attracting other proteins, but specificity is the degree to which an antibody can isolate a single target. Both of these properties are equally important to make a good quality antibody.”

Professor Cho presented a webinar (an online seminar http://www.acsbiot.org/index.php/2016-best-biot/) in September on this subject on behalf of the ACS. He and his research team are currently applying this knowledge to develop a highly specific and reactive antibody.

By: Adam M. Rainear

The Chemical and Biomolecular Engineering Department is pleased to announce Jennifer Pascal as an Assistant-Professor in Residence, who will mainly have a teaching emphasis for the department.

Joining UConn after spending three years teaching at her alma mater, Tennessee Technological University (TTU), Dr. Pascal attributes her passion for teaching and education as one of the main reasons for joining UConn.

“The school I was at – I thought – had a nice balance between research and teaching,” she said. “But, it turns out they’re really pushing research. [And] I really wanted to focus on teaching and engineering education.”

With her new role, Dr. Pascal is most looking forward to improving her classes and refining her teaching abilities.

“Just actually getting to focus on your classes, and try to make them good,” she said. “Trying new things, because you have time now to prepare and do some different activities and stuff like that. And then, getting to go to some of the workshops at CETL, and interacting with some of the folks over there. It’s been exciting, those were the meetings I always liked going to.”

In her first semester here in Storrs, Dr. Pascal co-taught Introduction to Chemical Engineering (CHEG 2103), in addition to Unit Operations and Process Simulation (CHEG 4142). In the upcoming spring semester, she will teach two advanced transport special topics courses and will co-teach the chemical engineering senior laboratory.

Dr. Pascal received her Ph.D. in Chemical Engineering from TTU in 2011, researching Modeling Electrokinetic-based Bioseparations and Learning Transport Phenomena for her dissertation. From there, she went on to begin her career at the University of New Mexico on a National Institutes of Health postdoctoral fellowship, where she could devote a portion of her fellowship to teaching at a minority serving institution in Albuquerque, New Mexico.

Though she doesn’t have specific research requirements, moving forward Dr. Pascal hopes to continue engaging in research with her new colleagues.

“I’m interested in engineering education research, so I’m trying to get some things going with that and build that up. Before I did mathematical modeling of bio-transport systems, so I’m open.”

Dr. Pascal denotes her father, a former television weatherman in Tennessee, for her passion of all-things science when she was younger.

“I grew up with all this science stuff around – he’s a big nerd – so, weather stations in our house and experiments all the time,” Pascal noted. “He got me a microscope when I was five – and growing up around that – I’m sure influenced me.”

It is with great sadness that we say farewell to our beloved friend and colleague Prof. Emeritus G. Michael Howard. Prof. Howard was a Professor and former Department Head of Chemical Engineering, as well as former Associate Dean for the School of Engineering during his tenure here at UConn (1961-97). He will be greatly missed.

By: Taylor Caron

Professor Yongku Cho of the Chemical and Biomolecular Engineering Department has received a research grant from the National Institute of Health, a primary Federal funding source, this past August. His research centers on engineering an antibody that could potentially elucidate the mechanism of neurotoxicity in Alzheimer’s disease.

The project, which is being led by Professor Cho, began in September with his graduate student Dan Li, and is focusing on what is known as the Tau protein. The Tau protein exists in brain tissue and is thought to result in neurodegeneration when improperly modified. According to Professor Cho, antibodies are a valuable tool in Alzheimer’s research because they are capable of recognizing these modifications, such as phosphorylation and acetylation of the Tau. However, a critical issue with many antibodies is that they bind unmodified Tau and proteins other than the desired target. This process is called cross-reactivity and can mislead research in Alzheimer’s disease. The focus of Professor Cho and his lab is to develop an antibody which will be more accurate in targeting the defective Tau alone.

“One study estimated that half of the antibodies currently sold on the market do not work as intended. A primary reason for this is cross-reactivity,” Professor Cho said.

Professor Cho’s project is entitled Early Detection of Tau Acetylation Using Ultra-High Affinity Antibodies. There are two primary functions to determine an antibody’s effectiveness: affinity and specificity. Affinity refers to the strength with which an antibody attracts other proteins, and specificity refers to an antibody’s ability so single out an individual protein like the Tau, without cross-reactivity. Professor Cho said much attention has been placed on affinity to the neglect of specificity, but that his project will focus on both.

“The proposal is about affinity and specificity, but I believe it is essential to develop a high-quality antibody that can both isolate the Tau and sufficiently attract it. Affinity and specificity go hand in hand,” he said.

Professor Cho spoke about what the Tau looks like under a harmful modification called acetylation, and how the grant from NIH will help him and his team detect it with high sensitivity, allowing to better elucidate its effect on Alzheimer’s disease.

“The Tau protein forms a tangle inside the brain that is a hallmark of Alzheimer’s disease,” Professor Cho said. “There are many forms or modifications of the protein, and one is known as acetylation which we believe may be the cause of the neurotoxicity.”

Professor Cho and his lab will be working with Dr. Benjamin Wolozin from Boston University to test their antibodies on human tissue samples. He is hopeful that this antibody could someday be used in detecting the early signs of Alzheimer’s disease, and enable the development of therapeutics.

By: Taylor Caron

The Chemical Engineering Graduate Student Association (ChEGSA) hosted a Halloween party for graduate students and CBE faculty on the Friday before Halloween.

The room in Engineering II was filled with video games, large pizzas, and tabletops games as CBE members mingled with some decked out in Halloween costumes.

Travis Omasta, a graduate student who organized the event, said the aim was to allow for faculty and students to meet and talk with another, which is often the catalyst for both friendship and networking.

“The main goal of many of our events, the Halloween party included, is to build comradery and community within the CBE graduates.” Omasta said. “This particular event was held on Friday afternoon during typical work hours so it is easy for students and faculty to come by and socialize.”

Introductions and lively conversation was abundant throughout the event. According to Omasta, this is the kind of function ChEGSA regularly hopes to provide to the department, and there are many more events to come.

“We consider this event successful as we have all of our events this year, with our primary focus of getting more students involved, especially the ones that don’t know as many people around campus,” he said. “ChEGSA also hosts enriching events such as rapid fire presentations competitions, seminars on job and real work skills, and practices for conference presentations.”

By: Taylor Caron

The Chemical Engineering Department is pleased to announce Matt Stuber as an Assistant Professor whose research focus will be on process systems and optimization.

Professor Stuber received his PhD in Chemical Engineering from MIT, and co-founded a company called WaterFX which is about making conventional approaches to water desalination more efficient and powered by renewables. He said that his work in the private sector was great experience as Director of Process Systems Engineering, and that he is excited to make the shift to academia to continue working on important challenges concerning sustainability and energy.

“WaterFX has been very successful, but I didn’t really find passion in its administration. I’m a scientist and an engineer,” Stuber said. “Sometimes too much of the tech industry is based on growth trajectories and not solving real problems. I decided to refocus my efforts on research and am very pleased to become a member of UConn’s CBE faculty.”

WaterFX, where Stuber led the efforts in all things technical, has gained much attention from national outlets like PBS, National Geographic, and even involvement with The White House, helping shape their efforts in addressing national water challenges. However, Professor Stuber is excited to work with UConn’s Institute for Advanced Systems Engineering which aligns with his experience and interests.

“The new institute has emphasized the kind of research values I consider really important. It’s a great up -and -coming institute which will be a massive force to be reckoned with,” he said.

Professor Stuber’s work at MIT focused on researching and developing theoretical mathematical tools for chemical and energy processes. His research was highly mathematical and he developed algorithms for advanced formal methods in robust and optimal design under uncertainty problems.

Professor Stuber’s research at UConn will continue to focus on process systems engineering, and in particular, rigorous design under uncertainty.

“Process systems is sort of a broad buzz word. It’s a subject of applied mathematics, computer science, and engineering. It applies systems-level thinking to engineered processes,” he said.

Professor Stuber said that his research will be somewhat similar to his work with WaterFx where he developed models and used advanced optimization methods to innovate processes for enhancing efficiency and augmenting them for renewable energy. The company’s ultimate goal is to reduce costs and enhance access to scarce natural resources through sustainable means.

“I’m definitely interested in solving real world problems. Water scarcity is directly related to issues of climate change which is a big part of what attracted me to the issue,” he said. “I’m incredibly glad to be a part of the CBE department to continue to progress this work which has timely and significant benefits to most industries as well as the natural environment.”

By: Taylor Caron

By: Taylor Caron

UConn Chemical Engineering graduate student Jian Ren has received two national awards for her innovative research on water purification. The North American Membrane Society (NAMS) awarded her a Student Fellowship Award this past May, and she will receive a Graduate Student Research Award from the American Institute of Chemical Engineering (AIChE) at the annual meeting this upcoming November.

Both awards are highly selective as the NAMS Fellowship is given to only three students annually, and the AIChE Research Award to only six or eight. Ren said she was very honored to receive the awards, especially the NAMS Fellowship.

“The NAMS Student Fellowship is the highest student award to receive from NAMS, so I am really honored and grateful to receive this recognition in the field of membrane science and technology,” she said. “This would not be possible without the continuous support from my advisor and colleagues.”

Ren has been working with Professor Jeffrey McCutcheon on an energy efficient and cost effective method of purifying water. Conventionally, a process called reverse osmosis is used in seawater desalination and wastewater treatment. Ren’s work uses a process called forward osmosis which utilizes natural osmotic tendency at a lower cost to separate water from contaminants. Her research focuses on developing innovative hollow fiber membranes (HFM) for this process. The HFM is a semi-permeable membrane which requires much less energy than the standard membrane used in reverse osmosis.

These membranes have a straw-like shape and can achieve a high packing density, Ren said. Not only is it more effective while enabling small footprint system, but it is easier to manufacture at a large scale

“The HFM is also self-supported, which makes it easy to prototype in academic labs and manufacture in industry,” she said.

Part of what makes Ren’s research so impressive is that she built her own hollow fiber spinning system at UConn from scratch.

“Professor McCutcheon encouraged me to build the system, and I accepted because I like to challenge myself. Unless you challenge yourself you never know you had such potential,” Ren said.

By Sydney Souder

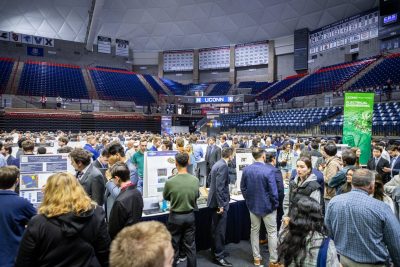

May 1, 2015 marked the School of Engineering’s much anticipated Senior Design Day. The Department of Chemical & Biomolecular Engineering showcased the projects of 13 teams at the event, a school-wide poster competition held on the floor of the Gampel Pavilion arena.

May 1, 2015 marked the School of Engineering’s much anticipated Senior Design Day. The Department of Chemical & Biomolecular Engineering showcased the projects of 13 teams at the event, a school-wide poster competition held on the floor of the Gampel Pavilion arena.

Each team of students spent the entirety of their senior year on a single open-ended capstone design project. The teams began their journeys with a written description of their project, and a faculty and an industry advisor to mentor them as they tackled the challenge.

Over the next eight months, students presented multiple oral presentations and submitted a range of written reports. The poster competition is the final step where the student’s designs are summarized on a 2’ by 3’ poster board display for the public.

On this ultimate design day, both the posters and students are judged. This year, CBE was pleased to host 14 industry experts to judge the posters. Half of these judges were UConn chemical engineering alumni. Each team of students had their poster and verbal pitch evaluated five times.

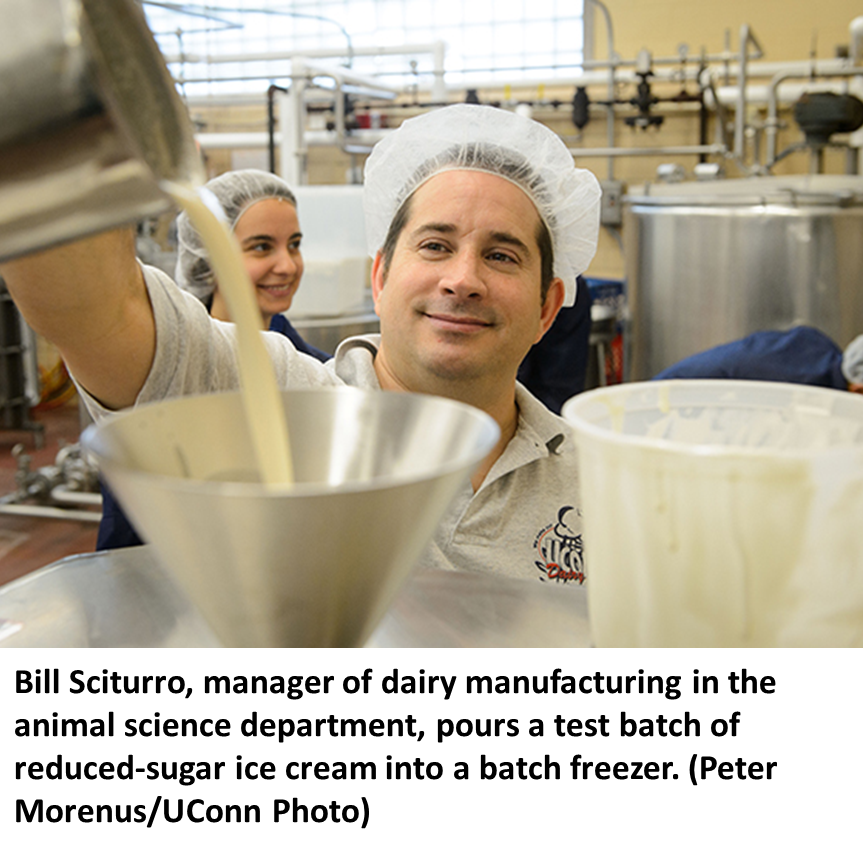

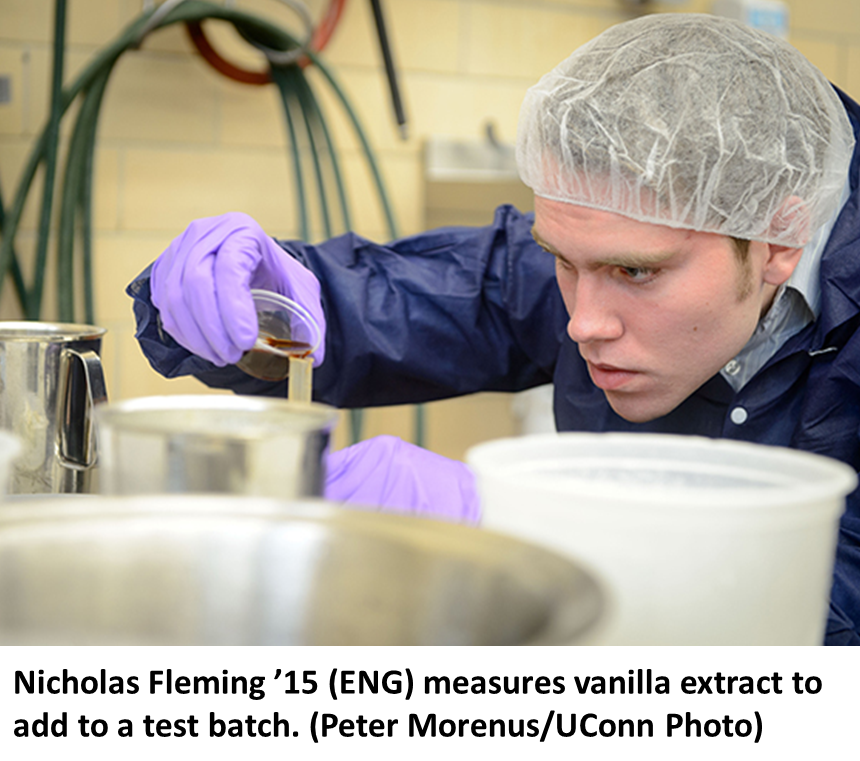

This year’s assortment of projects varied from inventing a human habitat on Mars, to designing wastewater treatments for Unilever. Visitors were even treated to samples of sugar-reduced ice cream developed by a student team for UConn’s Dairy Bar. The following teams earned the highest scores:

This year’s assortment of projects varied from inventing a human habitat on Mars, to designing wastewater treatments for Unilever. Visitors were even treated to samples of sugar-reduced ice cream developed by a student team for UConn’s Dairy Bar. The following teams earned the highest scores:

First place was awarded to Team 10 whose project was titled “Novel Production and Purification of Manganese Dioxide.” The team consisted of Nicole Beauregard, Gianna Credaroli, Andrea DiVenere, Naomi Tennakoon and Abbey Wangstrom, and they were advised by Dr. Bill Mustain. Duracell sponsored their project to produce and characterize a more pure electrolytic manganese dioxide for use in alkaline batteries. By incorporating electrolyte additives, impurities in the material can be decreased. A battery with higher capacity can improve Duracell sales, lessen the environmental burden of battery waste products, and enhance the consumers’ trust in their power.

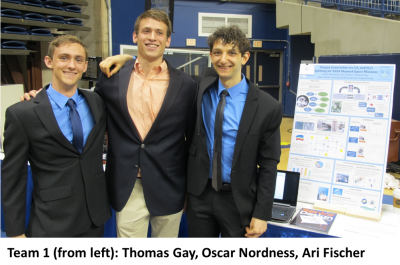

Second place was awarded to Team 1 for their project “Oxygen Generation via CO2 and H2O Splitting for NASA Manned Space Missions.” Thomas Gay, Ari Fischer and Oscar Nordness made up Team 1, and they were advised by Dr. George Bollas. Team 1 used a chemical looping process to implement a metal oxide oxygen carrier for the Oxygen Generation System (OGS) in NASA’s International Space Station. Potential benefits of their system could reduce size and mass of the OGS as well as improve its electrical efficiency.

Second place was awarded to Team 1 for their project “Oxygen Generation via CO2 and H2O Splitting for NASA Manned Space Missions.” Thomas Gay, Ari Fischer and Oscar Nordness made up Team 1, and they were advised by Dr. George Bollas. Team 1 used a chemical looping process to implement a metal oxide oxygen carrier for the Oxygen Generation System (OGS) in NASA’s International Space Station. Potential benefits of their system could reduce size and mass of the OGS as well as improve its electrical efficiency.

Third Place was received by Team 4 for their project “Defluoridation of Ethiopian Groundwater for Human Consumption.” Dr. Doug Cooper advised the group of Jack Edmonds, Gabriella Frey and George Shaw. Due to the pressing health concerns from fluoride contaminated water, the goal of their project was to design a cost effective method of removing upwards of 90% of fluoride ions in groundwater used for human consumption. Current methods use imported technologies from China which are expensive and prone to shipping delays, especially in third world countries. Team 4 created a new method to defluoride water using magnesium oxide, a mineral already existing in Ethiopia.

“Design day is wonderful conclusion to the undergraduate journey,” says Dr. Cooper, professor and head of the department. “Our students show off their hard work, and visitors enjoy learning about the creative and sophisticated solutions they have developed.”

Republished with permission of Momentum,

a School of Engineering electronic publication.

Anson Ma, Assistant Professor in the Department of Chemical and Biomolecular Engineering and the Institute of Materials Science, has been awarded the prestigious Arthur B. Metzner Early Career Award.

Anson Ma, Assistant Professor in the Department of Chemical and Biomolecular Engineering and the Institute of Materials Science, has been awarded the prestigious Arthur B. Metzner Early Career Award.

The award, which comes with a plaque and a $7,500 honorarium, goes to a young person who has made significant accomplishments in rheology, which is the study of the flow of matter.

Ma was nominated by Malcolm Mackley, Emeritus Professor at Cambridge University, who worked with Ma from 2005 to 2009 on the rheology of carbon nanotubes (CNTs) suspended in epoxy and acrylic resins. In his nomination, Mackley wrote:

Anson, with his meticulous approach to science and rheology made sense of difficult experiments. Working together with Prof Paco Chinesta, who is now at Ecole Centrale des Nantes, Anson was the glue that made the link between experiment and some high level suspension rheological modeling.

At UConn, Ma and his team apply experimental and theoretical rheology to a broad range of important application areas. Since 2011, Ma has supervised three postdoctoral fellows, four PhD students, and three visiting students from France. He has also hosted 21 undergraduate students, three high school teachers, and eight

minority high school students to provide them with early research experience related to rheology. To engage younger students and the local community, Ma has chosen food science and, more specifically, rheology of culinary foams and emulsions as the theme for his outreach plan.

By Sydney Souder

Dr. Mu-Ping Nieh hopes to discover elusive secrets in the nano-structures of functional materials using the new X-ray scattering machine he and his collaborators have secured for the University of Connecticut. His work focuses on the study of soft materials, and in particular, understanding their nanoscopic structures to optimize their functions. With the new, top-of-the-line Nanostar SAXS instrument, Dr. Nieh expects to take his research to the next level.

Dr. Mu-Ping Nieh hopes to discover elusive secrets in the nano-structures of functional materials using the new X-ray scattering machine he and his collaborators have secured for the University of Connecticut. His work focuses on the study of soft materials, and in particular, understanding their nanoscopic structures to optimize their functions. With the new, top-of-the-line Nanostar SAXS instrument, Dr. Nieh expects to take his research to the next level.

Acquired through a competitive National Science Foundation Major Research Instrumentation (MRI) Grant, the Nanostar SAXS is a sophisticated instrument that allows researchers to probe the nanostructures of materials in a large sample area. Specifically, it can identify the shape, size, aggregation behavior, polydispersity, interparticle interactions and surface (interfacial) area of a system.

The instrument works by sending an X-ray beam at a sample of interest. As the X-ray hits the sample, the beam diffracts and scatters into different angles. This scatter pattern can reveal information on the nanostructure of the sample. The method can be applied to a broad range of materials including liquids, solids, thin films and gels. This makes the tool valuable for those investigating the structure-property relationship substances. It also enables industry partners to perform fundamental research and to design and develop materials . Dr. Nieh hopes to build on this interest by establishing a regional center for nanostructural characterization for UConn and industrial partners.

Beyond current and collaborative research, having access to the instrument is also an invaluable opportunity for students. “The Nanostar instrument will be used to train the next generation of scientists and engineers through hands-on research experience,” says Dr. Nieh. “I encourage potential research and industry partners to contact me if they would like to learn more.” Dr. Nieh will teach a webinar course “Small Angle X-Ray Scattering (SAXS) for Nanostructural Characterization” to the public through the Institute of Materials Science’s Affiliate Program later this year.

By Sydney Souder

Dr. George Bollas, Assistant Professor of the CBE Department, is the first recipient of the Office of Undergraduate Research’s (OUR) Faculty Mentorship Excellence Award. He received the award at the 18th Annual Frontiers in Undergraduate Research Poster Exhibition on Friday, April 10, 2015.

Dr. George Bollas, Assistant Professor of the CBE Department, is the first recipient of the Office of Undergraduate Research’s (OUR) Faculty Mentorship Excellence Award. He received the award at the 18th Annual Frontiers in Undergraduate Research Poster Exhibition on Friday, April 10, 2015.

With this award, OUR recognizes the critically significant role that mentors play in supporting their undergraduates’ research and creative activity. A committee of OUR Peer Research Ambassadors selected one faculty recipient and one graduate student for the Mentorship Excellence Award recognizing their dedication to their students.

Ari Fischer, one of his mentees who contributed to his nomination, presented the plaque to Dr. Bollas. Fischer commended Dr. Bollas’ extraordinary commitment to challenging and supporting his students. He attributes Dr. Bollas’ influence to helping his mentees achieve their research, personal, and professional goals. Dr. Bollas has helped his students formulate their own research projects, apply for fellowships and publish their own work.

Bollas’ current research group consists of seven Ph.D. students, one Masters student, and 10 undergraduates. Fischer asserts that Dr. Bollas’s dedication is not limited to just those in his lab, but to all of his students; he pushes them to get the most out of their education.

Although honored by his new plaque, Dr. Bollas explained what he considers his real prize. “At the end of the day we’re given the opportunity to spend time with these amazing, fresh minds hungry for knowledge and work, and that is what is most rewarding.”

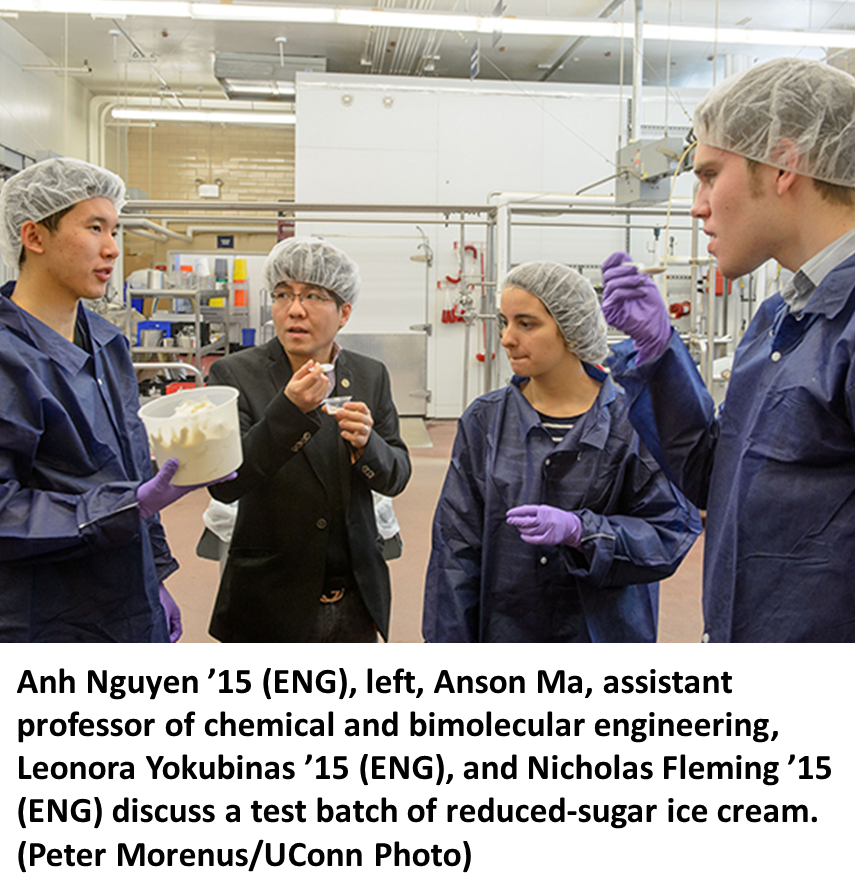

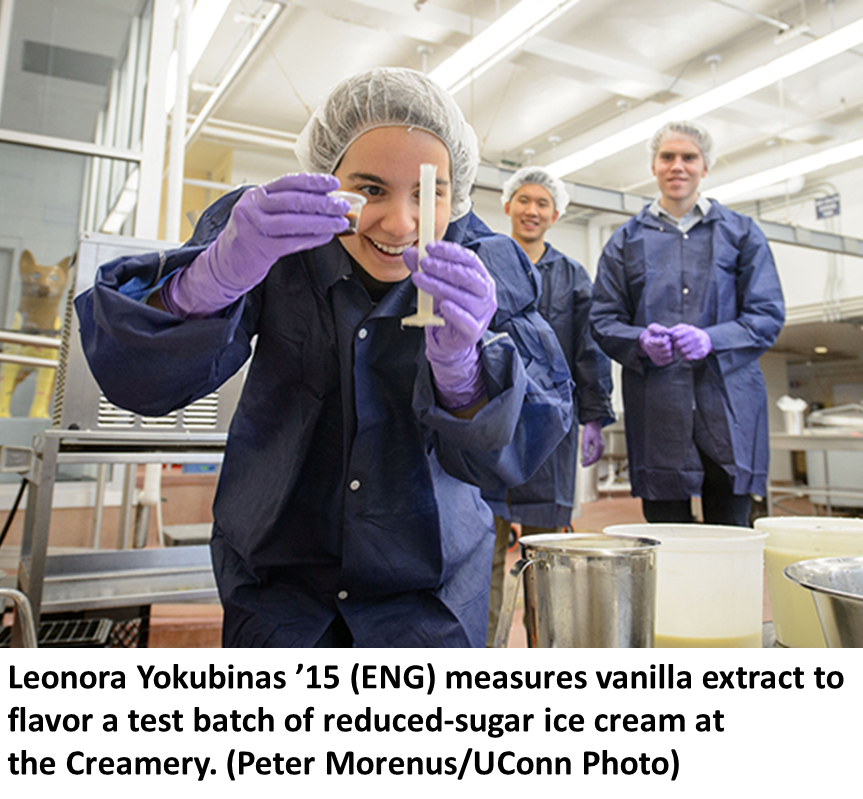

What happens when you mix UConn’s renowned Creamery and its top-notch Chemical Engineering department? If things go right, you get an ice cream that forgoes traditional sugar, but still earns a place along with the famously delicious ice creams at the Dairy Bar.

What happens when you mix UConn’s renowned Creamery and its top-notch Chemical Engineering department? If things go right, you get an ice cream that forgoes traditional sugar, but still earns a place along with the famously delicious ice creams at the Dairy Bar.