The Chemical & Biomolecular Engineering Department would like to congratulate Professor Anson Ma on being named a 2020 Air Force Research Lab Summer Faculty Fellow. More details regarding this prestigious fellowship can be found here.

Author: Orlando E

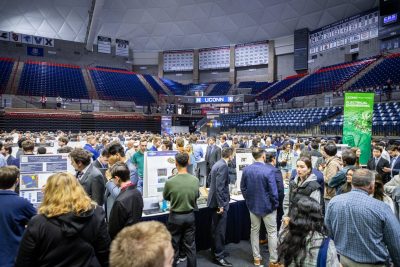

Senior Design Day 2015

By Sydney Souder

May 1, 2015 marked the School of Engineering’s much anticipated Senior Design Day. The Department of Chemical & Biomolecular Engineering showcased the projects of 13 teams at the event, a school-wide poster competition held on the floor of the Gampel Pavilion arena.

May 1, 2015 marked the School of Engineering’s much anticipated Senior Design Day. The Department of Chemical & Biomolecular Engineering showcased the projects of 13 teams at the event, a school-wide poster competition held on the floor of the Gampel Pavilion arena.

Each team of students spent the entirety of their senior year on a single open-ended capstone design project. The teams began their journeys with a written description of their project, and a faculty and an industry advisor to mentor them as they tackled the challenge.

Over the next eight months, students presented multiple oral presentations and submitted a range of written reports. The poster competition is the final step where the student’s designs are summarized on a 2’ by 3’ poster board display for the public.

On this ultimate design day, both the posters and students are judged. This year, CBE was pleased to host 14 industry experts to judge the posters. Half of these judges were UConn chemical engineering alumni. Each team of students had their poster and verbal pitch evaluated five times.

This year’s assortment of projects varied from inventing a human habitat on Mars, to designing wastewater treatments for Unilever. Visitors were even treated to samples of sugar-reduced ice cream developed by a student team for UConn’s Dairy Bar. The following teams earned the highest scores:

This year’s assortment of projects varied from inventing a human habitat on Mars, to designing wastewater treatments for Unilever. Visitors were even treated to samples of sugar-reduced ice cream developed by a student team for UConn’s Dairy Bar. The following teams earned the highest scores:

First place was awarded to Team 10 whose project was titled “Novel Production and Purification of Manganese Dioxide.” The team consisted of Nicole Beauregard, Gianna Credaroli, Andrea DiVenere, Naomi Tennakoon and Abbey Wangstrom, and they were advised by Dr. Bill Mustain. Duracell sponsored their project to produce and characterize a more pure electrolytic manganese dioxide for use in alkaline batteries. By incorporating electrolyte additives, impurities in the material can be decreased. A battery with higher capacity can improve Duracell sales, lessen the environmental burden of battery waste products, and enhance the consumers’ trust in their power.

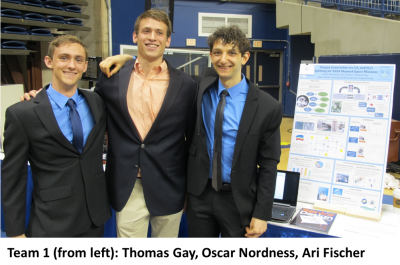

Second place was awarded to Team 1 for their project “Oxygen Generation via CO2 and H2O Splitting for NASA Manned Space Missions.” Thomas Gay, Ari Fischer and Oscar Nordness made up Team 1, and they were advised by Dr. George Bollas. Team 1 used a chemical looping process to implement a metal oxide oxygen carrier for the Oxygen Generation System (OGS) in NASA’s International Space Station. Potential benefits of their system could reduce size and mass of the OGS as well as improve its electrical efficiency.

Second place was awarded to Team 1 for their project “Oxygen Generation via CO2 and H2O Splitting for NASA Manned Space Missions.” Thomas Gay, Ari Fischer and Oscar Nordness made up Team 1, and they were advised by Dr. George Bollas. Team 1 used a chemical looping process to implement a metal oxide oxygen carrier for the Oxygen Generation System (OGS) in NASA’s International Space Station. Potential benefits of their system could reduce size and mass of the OGS as well as improve its electrical efficiency.

Third Place was received by Team 4 for their project “Defluoridation of Ethiopian Groundwater for Human Consumption.” Dr. Doug Cooper advised the group of Jack Edmonds, Gabriella Frey and George Shaw. Due to the pressing health concerns from fluoride contaminated water, the goal of their project was to design a cost effective method of removing upwards of 90% of fluoride ions in groundwater used for human consumption. Current methods use imported technologies from China which are expensive and prone to shipping delays, especially in third world countries. Team 4 created a new method to defluoride water using magnesium oxide, a mineral already existing in Ethiopia.

“Design day is wonderful conclusion to the undergraduate journey,” says Dr. Cooper, professor and head of the department. “Our students show off their hard work, and visitors enjoy learning about the creative and sophisticated solutions they have developed.”

Anson Ma Wins Arthur B. Metzner Early Career Award

Republished with permission of Momentum,

a School of Engineering electronic publication.

Anson Ma, Assistant Professor in the Department of Chemical and Biomolecular Engineering and the Institute of Materials Science, has been awarded the prestigious Arthur B. Metzner Early Career Award.

Anson Ma, Assistant Professor in the Department of Chemical and Biomolecular Engineering and the Institute of Materials Science, has been awarded the prestigious Arthur B. Metzner Early Career Award.

The award, which comes with a plaque and a $7,500 honorarium, goes to a young person who has made significant accomplishments in rheology, which is the study of the flow of matter.

Ma was nominated by Malcolm Mackley, Emeritus Professor at Cambridge University, who worked with Ma from 2005 to 2009 on the rheology of carbon nanotubes (CNTs) suspended in epoxy and acrylic resins. In his nomination, Mackley wrote:

Anson, with his meticulous approach to science and rheology made sense of difficult experiments. Working together with Prof Paco Chinesta, who is now at Ecole Centrale des Nantes, Anson was the glue that made the link between experiment and some high level suspension rheological modeling.

At UConn, Ma and his team apply experimental and theoretical rheology to a broad range of important application areas. Since 2011, Ma has supervised three postdoctoral fellows, four PhD students, and three visiting students from France. He has also hosted 21 undergraduate students, three high school teachers, and eight

minority high school students to provide them with early research experience related to rheology. To engage younger students and the local community, Ma has chosen food science and, more specifically, rheology of culinary foams and emulsions as the theme for his outreach plan.

Grad Student Spotlight: Andrea Kadilak

By Jayna Miller

The Chemical Engineering graduate program at UConn provides the opportunity for students to obtain a thorough understanding of the principles of chemical engineering and gain the practical skills needed to succeed in the workplace. Students have the chance to get involved in a number of useful research and teaching opportunities to better prepare for their future.

The Chemical Engineering graduate program at UConn provides the opportunity for students to obtain a thorough understanding of the principles of chemical engineering and gain the practical skills needed to succeed in the workplace. Students have the chance to get involved in a number of useful research and teaching opportunities to better prepare for their future.

Grad student Andrea Kadilak has taken advantage of many of the programs and activities that UConn had to offer. Her most rewarding experience during her years at the university was her involvement with the NSF GK-12 Fellowship Program, where she worked with high school students to inspire an interest in science.

“I worked with students at Windham Tech to raise awareness of career options in physics, chemistry, and engineering – I also showcased the fun side of science through experimental demonstrations,” she says.

In addition to the NSF GK-12 Fellowship, Andrea was also involved in a number of on-campus engineering groups. She is currently the Chairperson for the CBE Grad Student Association, and is the Activities Director for the local chapter of AIChE.

“These leadership positions provide an opportunity for me to plan events, network, and organize meetings that bring together all of the engineering programs at UConn, to create a collaborative atmosphere and provide a wide variety of research opportunities for students,” she says.

These positions were not Andrea’s first leadership and work experiences. Prior to attending UConn, she worked as a Process Engineer at Solutia for two years, but decided that she wanted to return to research in a university setting.

Andrea’s research currently focuses on the NSF EFRI Termite Grant, which involves working with a team of engineers, including CBE professor Leslie Shor, to simulate the termite digestive tract in a micro-fluidic device. Termites are able to efficiently break down cellulose and other woody materials into biofuels to use as a food source. Through this research, the team hopes to culture the digestive bacteria in the micro-fluidic device in order to observe it, and perhaps recreate the biofuels, which will have an environmental benefit because it can reduce fuel needs.

Andrea has received multiple accolades for her research at UConn. She received the Women’s Initiative Committee Travel Award at the Minnesota AIChE Meeting in 2011, and earned 2nd place in the Poster Presentation Competition. In addition, she was the recipient of an ACS Meeting Certificate of Merit in 2012.

In the future, Andrea hopes to work in industry, but also to continue her personal research. She enjoyed working in a chemical plant in the past, but would like to achieve a balance and bridge the gap between research and the implementation of research practices in a process.

AIChE 2013 Annual Conference Draws Strong Attendance from CBE Undergrads

By Jayna Miller

The University of Connecticut Chemical & Biomolecular Engineering undergraduate students recently attended the AIChE 2013 Annual Meeting in San Francisco. The AIChE Annual Meeting is an educational forum for chemical engineers focused on research, growth, and innovation. Industry and academic professionals discussed a variety of topics relating to new research, technologies, and studies in chemical engineering.

The University of Connecticut Chemical & Biomolecular Engineering undergraduate students recently attended the AIChE 2013 Annual Meeting in San Francisco. The AIChE Annual Meeting is an educational forum for chemical engineers focused on research, growth, and innovation. Industry and academic professionals discussed a variety of topics relating to new research, technologies, and studies in chemical engineering.

During the conference, undergraduate students attended events designed to present current research on the latest advances in core areas of chemical engineering, while also covering specific topical areas. Specialty topics included related fields such as alternative energy, sustainability, bioengineering, and process safety.

Several undergrad students gave presentations on their research. William Hale, working with Chemical & Biomolecular professors Ranjan Srivastava and Richard Parnas, presented “Design Optimization by Response Surface Methodology for Continuous Fermentative Production of 1,3 Propanediol From Waste Glycerol By Product of Biodiesel Processes.” Oscar Nordness, a Junior working with Zhiquan Zhou and professor George Bollas, presented in both the oral and poster competitions, and won the 2nd award in the Student Poster Competition. Oscar’s poster title was “Reactivity Analysis of Ni, Cu, Fe Oxygen Carriers in Fixed Bed Chemical Looping Combustion.” His oral presentation was “On the kinetics of Ni-based oxygen carrier reduction and oxidation studied in thermogravimetric analysis and fixed-bed reactors.”

Grad Student Spotlight: Yixin Liu

By Jayna Miller

At the University of Connecticut, Chemical Engineering graduate students enjoy access to an outstanding combination of academic excellence, student resources, financial support, and a vibrant community.

At the University of Connecticut, Chemical Engineering graduate students enjoy access to an outstanding combination of academic excellence, student resources, financial support, and a vibrant community.

For grad student Yixin Liu, this is especially true. “I really appreciate that the program gave me so many opportunities to attend different conferences to present my work and communicate with others, such as AIChE annual meeting every year,” she says. She also enjoys the setting of UConn’s campus – which is very different from her hometown.

Yixin moved to Connecticut in 2010 after completing her undergraduate education at Zhejiang University, which is near the east seacoast of China. UConn was her first offer, and after admiring the respected graduate program and the helpful financial support she would receive, she decided to choose UConn to complete her Ph.D.

During her time at UConn, Yixin has worked with Dr. Yu Lei on the development of a high temperature gas sensor which will improve combustion efficiency.

“Real-time, in-situ monitoring and control of combustion-related gases are a top priority in many industrial applications, such as power plant, automotive, metal processing and casting, chemical and petrochemical industries,” she says. These high temperature gas sensors are designed to monitor gas concentrations after combustion and to optimize the combustion process via feedback system, which can improve the combustion efficiency, save more energy, and also reduce the emission of pollutants.

“Our goal is to develop sensors which can be operated right after combustion, so we can immediately get the full picture of combustion conditions and provide more precise control of combustion,” Yixin says.

Yixin’s work on this research throughout her graduate career has been publicly recognized. She has published 10 papers in various scientific journals, four of which she was the lead author. Following her graduation this fall, Yixin plans to work in industry, preferably at a large company. She would especially enjoy continuing her research in a practical, applied setting.

Grad Student Spotlight: Jason White

By Jayna Miller

The chemical engineering graduate program at the University of Connecticut is comprised of bright, innovative leaders who are motivated by change and challenge. The program offers the opportunity for students to enhance their skills and develop their potential.

The chemical engineering graduate program at the University of Connecticut is comprised of bright, innovative leaders who are motivated by change and challenge. The program offers the opportunity for students to enhance their skills and develop their potential.

One student who can attest to the merits of this program is Jason White. Jason completed his undergraduate degree at UConn, and decided he wanted to continue his research here after enjoying his undergraduate experience. Throughout his time at UConn, Jason has worked with Dr. Ranjan Srivastava on analyzing biological systems and developing computational tools that deal with human health-related problems. These analyses have implications towards personalized medicine for each patient.

“Our goal is to use computational tools to understand how a disease progresses and to analyze whether treatments for patients are optimal,” Jason says. Genetic algorithms are one such method that Jason employs to develop mathematical models of biological systems from experimental data sets. He anticipates that these models could be used to help personalize medicinal treatments on a patient-by-patient basis. For instance, he created a mathematical model of an oral mucositis system, which can be simulated to help predict the outcome and potential treatment options for patients suffering with this disease.

In addition to his research, Jason has also been involved in a number of campus activities. His favorite was the GK-12 Program sponsored by the National Science Foundation, which allowed him to work once a week with technical high school students.

“I enjoyed the GK-12 experience – it gave me the freedom to develop lessons and projects, but also to continue my research as well,” he says. Through this program, he was able to work with students to build a compost water-heating system, which was presented at Lemelson-MIT’s Eureka Fest. Jason has also helped motivate students to get involved in engineering by tutoring undergraduates from Grasso Tech and by serving as a TA at UConn. In the future, Jason plans to pursue these interests and become a professor, so he can maintain the balance between teaching and his research.

During his time at UConn, Jason has earned a number of accolades for his work, such as a Unilever Scholarship, an Arnold Griffin Scholarship, and an NSF GK-12 Fellowship. He has also published two proceedings in the Journal of Clinical Oncology.

Dr. William Mustain Receives DOE Early Career Research Program Award

Republished with permission of Momentum,

a School of Engineering electronic publication.

By Jayna Miller (CLAS Dec. ’13)

Dr. William Mustain, an assistant professor of Chemical & Biomolecular Engineering, is the recipient of a U.S. Department of Energy (DOE) Office of Science Early Career Award, which is one of the most competitive in the United States, with only 65 awarded annually. The Early Career Research Program supports the research pursuits of exceptional young scientists, and creates career opportunities in various research fields. Dr. Mustain’s five-year, $800,000 award was presented by the Office of Basic Energy Science.

Dr. William Mustain, an assistant professor of Chemical & Biomolecular Engineering, is the recipient of a U.S. Department of Energy (DOE) Office of Science Early Career Award, which is one of the most competitive in the United States, with only 65 awarded annually. The Early Career Research Program supports the research pursuits of exceptional young scientists, and creates career opportunities in various research fields. Dr. Mustain’s five-year, $800,000 award was presented by the Office of Basic Energy Science.

The award will bring new equipment to the university and fund two graduate and two undergraduate students over the life of the grant. Dr. Mustain’s proposal, “Room Temperature Electrochemical Upgrading of Methane to Oxygenate Fuels,” will focus on the development of a new type of electrochemical device that converts methane, from natural gas or biogas, to liquid fuels, like methanol, at room temperature. This low temperature operation is a significant improvement over state-of-the-art methane-to-fuels processes that operate at very high temperatures, sometimes more than 900°C. They also generally convert methane to syngas then employ a second process to convert the syngas to other chemicals and fuels. These extra steps add both cost and complexity to the process.

According to Dr. Mustain, the research team will focus on understanding the fundamental mechanisms for the transformation of methane to methanol at ultra-low temperatures, bypassing the syngas intermediate, as well as determining the optimal design conditions to maximize methane conversion and methanol selectivity.

Perhaps the most exciting aspect of this process is that it is able to operate at or near room temperature (20-50°C), which has a number of advantages. “There will be lower energy required for the process, and much lower cost because you do not need high quality heat and you have a wider range of materials that you can consider,” said Dr. Mustain. He hopes to leverage all of the work that has been done on other electrochemical devices, like batteries and fuel cells, over the last 20 years to make rapid improvements on his prototype.

Perhaps the most exciting aspect of this process is that it is able to operate at or near room temperature (20-50°C), which has a number of advantages. “There will be lower energy required for the process, and much lower cost because you do not need high quality heat and you have a wider range of materials that you can consider,” said Dr. Mustain. He hopes to leverage all of the work that has been done on other electrochemical devices, like batteries and fuel cells, over the last 20 years to make rapid improvements on his prototype.

There are a variety of practical applications for this research. For instance, methanol can be used as a direct energy carrier, and as a fuel source for small portable power applications or cars using a direct methanol fuel cell. Methanol is also one of the top 25 industrial chemicals in the world, which means it has a range of uses. In addition, it can be easily converted to formaldehyde, which is another top 25 industrial chemical.

Dr. Mustain’s previous research has involved the design of new catalyst materials for fuel cells, capacitors and lithium-ion batteries. He also has received the Illinois Institute of Technology Young Alumni Award. For more about his DOE-funded research, please visit http://science.energy.gov/early-career/.

Podcast: Allison MacKay REU and RET Programs

Podcast: Salute to the Troops

Podcast: McCutcheon and Son

CBE Welcomes 5 New Faculty

Following an especially ambitious recruiting year, the Chemical & Biomolecular Engineering (CBE) Department is excited to announce that 5 impressive new faculty members will join us for the fall 2013 and spring 2014 academic terms. The leap in faculty hiring is rooted in President Susan Herbst’s 2012 announcement that UConn will hire 290 new tenured/tenure track faculty members – in addition to filling vacancies – across the university by 2016.

All bring substantial academic credentials that will strengthen UConn Engineering programs. The new faculty members are profiled briefly below.

Kelly Burke joins the Chemical & Biomolecular Engineering Department, and has an appointment in the Polymer Program of the Institute of Materials Science. Dr. Burke, who joins UConn under the Eminent Faculty Initiative, earned her PhD at Case Western Reserve University in 2010 and brings expertise in protein modification strategies, tissue engineering, structure-property relationships of liquid crystals, and biocompatible multifunctional polymeric materials. Dr. Burke was a post-doctoral associate at Tufts University (2010-13), where she received an NIH National Research Service Award Fellowship.

Kelly Burke joins the Chemical & Biomolecular Engineering Department, and has an appointment in the Polymer Program of the Institute of Materials Science. Dr. Burke, who joins UConn under the Eminent Faculty Initiative, earned her PhD at Case Western Reserve University in 2010 and brings expertise in protein modification strategies, tissue engineering, structure-property relationships of liquid crystals, and biocompatible multifunctional polymeric materials. Dr. Burke was a post-doctoral associate at Tufts University (2010-13), where she received an NIH National Research Service Award Fellowship.

Yongku Cho joins the Chemical & Biomolecular Engineering Department. He received his PhD from the University of Wisconsin – Madison in 2010. Dr. Cho’s research centers on protein engineering, optogenetics, neuroimaging and molecular neurobiology. He was most recently a post-doctoral researcher at the Massachusetts Institute of Technology, where his work involved the molecular engineering of light-activated proteins.

Yongku Cho joins the Chemical & Biomolecular Engineering Department. He received his PhD from the University of Wisconsin – Madison in 2010. Dr. Cho’s research centers on protein engineering, optogenetics, neuroimaging and molecular neurobiology. He was most recently a post-doctoral researcher at the Massachusetts Institute of Technology, where his work involved the molecular engineering of light-activated proteins.

Luyi Sun joins the Chemical & Biomolecular Engineering Department, and has an appointment in the Polymer Program of the Institute of Materials Science. Dr. Sun, who joins UConn under the Eminent Faculty Initiative, received his PhD at the University of Alabama in 2004 and brings expertise in multi-functional nanostructured materials; polymeric materials and new polymer processing development; layered compounds; green science and engineering; hydrates and porous materials for energy storage. He was an assistant professor of chemistry at Texas State University (2009-13) and was a post-doctoral fellow at both Texas A&M and the University of Alabama.

Luyi Sun joins the Chemical & Biomolecular Engineering Department, and has an appointment in the Polymer Program of the Institute of Materials Science. Dr. Sun, who joins UConn under the Eminent Faculty Initiative, received his PhD at the University of Alabama in 2004 and brings expertise in multi-functional nanostructured materials; polymeric materials and new polymer processing development; layered compounds; green science and engineering; hydrates and porous materials for energy storage. He was an assistant professor of chemistry at Texas State University (2009-13) and was a post-doctoral fellow at both Texas A&M and the University of Alabama.

Julia Valla joins the Chemical & Biomolecular Engineering Department with expertise in the design and development of novel catalysts for industrial applications and design of new, emerging technologies and processes for the clean and sustainable energy production. She earned her PhD at Aristotle University of Thessaloniki, Greece in 2005. Dr. Valla was previously an assistant research professor in CMBE and the Center for Clean Energy Engineering and, earlier in her career, a Project Leader for Rive Technology Inc.

Julia Valla joins the Chemical & Biomolecular Engineering Department with expertise in the design and development of novel catalysts for industrial applications and design of new, emerging technologies and processes for the clean and sustainable energy production. She earned her PhD at Aristotle University of Thessaloniki, Greece in 2005. Dr. Valla was previously an assistant research professor in CMBE and the Center for Clean Energy Engineering and, earlier in her career, a Project Leader for Rive Technology Inc.

Kristina Wagstrom joins the Chemical & Biomolecular Engineering Department as the Northeast Utilities Assistant Professor of Environmental Engineering Education. She brings expertise in sourcing and modeling atmospheric particulates, air pollutants, health impacts of atmospheric particulate matter deposition, and air quality models. Dr. Wagstrom received her PhD from Carnegie Mellon University in 2009. She conducted post-doctoral research at the University of Minnesota (2009-12), and was an AAAS Science and Technology Policy Fellow at the U.S. EPA (2012-13).

Kristina Wagstrom joins the Chemical & Biomolecular Engineering Department as the Northeast Utilities Assistant Professor of Environmental Engineering Education. She brings expertise in sourcing and modeling atmospheric particulates, air pollutants, health impacts of atmospheric particulate matter deposition, and air quality models. Dr. Wagstrom received her PhD from Carnegie Mellon University in 2009. She conducted post-doctoral research at the University of Minnesota (2009-12), and was an AAAS Science and Technology Policy Fellow at the U.S. EPA (2012-13).

CBE Will Host the 2014 AIChE Northeast Regional Student Conference

After a round of competitive bidding, it was announced that the Chemical & Biomolecular Engineering Department at the University of Connecticut will host the 2014 AIChE Northeast Regional Student Conference.

To be held in the spring of 2014, the regional conference is a place where students from schools around the northeast will come together to share their undergraduate research experiences, attend workshops, and network with other students and local companies that will sponsor the event. Highlights of the conference will include the undergraduate paper and poster competitions, and the highly anticipated Chem-E-Car competition.

Regional winners from all of these events will earn the opportunity to compete on the national stage at the annual professional meeting, which will be held in Atlanta in Fall 2014. The student executive board will begin planning for this event now, and companies or alumni that may be interested in participating, please contact Professor Daniel Burkey.

Friendly Competition Produces “Eggcelent” Results

Republished with permission from Momentum, a School of Engineering electronic publication.

On Thursday, May 30th, UConn’s GK-12 program hosted the second annual Engineering Design Challenge Competition, involving student teams from Connecticut’s Technical High School System, at the Storrs campus. The theme of this year’s competition was “Reverse Engineering Egg Crash Car.”

In the good-natured competition, the student teams were required to apply core engineering principles in a deceptively simple, fun and engaging way while pitting their engineering knowhow against that of other Tech School students. The participating teams were the top performers in contests held at their home Tech Schools.

In the Egg Crash Car competition, the teams were charged with building a racecar – using only the materials provided – capable of safely transporting an uncooked egg through a variety of challenges without the precious cargo breaking.

Among the materials available were Ziplock® bags, wheels, balloons, straws, pom-poms, mouse traps, fishing line, tape, poly-fill stuffing, cotton balls and rubber bands. These raw materials produced a variety of vehicles, from sleek rectangular entries to zany-looking “Mad Max” style vehicles adorned with cotton-ball armor. For each vehicle, it was stipulated that the egg “passenger” had to be removable.

The GK-12 Fellows designed three rigorous tests for the vehicles: a rear impact test, in which a suspended wooden mallet was released from three different angles into the rear of the vehicle; a rollover test, in which vehicles were released at different angles from the top of a four-foot plane; and a head-on collision test, in which CO2 canisters were attached to the rear of each vehicle as a propulsion system that carried the vehicles into a cinderblock wall. For each test, the aim was to keep the vehicle and its egg cargo intact. Other criteria included the vehicle production costs, speed and structural integrity.

In the end, the Tech School students enjoyed a fun day of friendly competition and came away with a better appreciation of core engineering concepts such as performance-based testing, tradeoffs between material cost and quality and the iterative and challenging nature of the design process.

The competition brought together teams from the Academy of Engineering and Green Technology, Howell Cheney Technical High School, Harvard H. Ellis Technical High School, E.C. Goodwin Technical High School, Ella T. Grasso Southeastern Technical High School, Norwich Technical High School, A.I. Prince Technical High School, Vinal Technical High School, and Windham Technical High School.

The teams – along with fellow students who did not compete – were mentored throughout the 2012-13 academic year by UConn Engineering doctoral candidates who are committed to helping introduce engineering concepts in Tech School classrooms. The 2012-13 GK-12 Fellows included Juan Pablo Correa Baena (Environmental Engineering); Lu Han, Andrea Kadilak, Joseph Parisi and Rebecca Rubinstein (all in Chemical Engineering); Justin Roller and Michael Zilm (Materials Science & Engineering); and Lou Bachenheimer and Nick Curtis (Mechanical Engineering).

The GK-12 (Graduate STEM Fellows in K-12 Education) program is an innovative educational program sponsored by the National Science Foundation. It aims to provide teaching resources (in the form of graduate students in the engineering sciences) to classrooms in the state of Connecticut Technical High School System. Dr. Doug Cooper is the Principal Investigator of UConn’s GK-12 program.

Dr. George Bollas Receives ACS PRF Doctoral New Investigator Award

By Jayna Miller

Dr. George Bollas, an assistant professor in the Department of Chemical and Biomolecular Engineering, is the recipient of a prestigious ACS Petroleum Research Fund Doctoral New Investigator Award. The ACS PRF programs support innovative research in the petroleum field and promote the development of promising engineers and scientists. The award program provides career opportunities to young faculty and their undergraduate and graduate students by supporting advanced scientific research. The goals of the American Chemical Society Petroleum Research Fund are to support fundamental research in the petroleum field and develop the next generation of engineers and scientists through the support of advanced scientific education.

Dr. George Bollas, an assistant professor in the Department of Chemical and Biomolecular Engineering, is the recipient of a prestigious ACS Petroleum Research Fund Doctoral New Investigator Award. The ACS PRF programs support innovative research in the petroleum field and promote the development of promising engineers and scientists. The award program provides career opportunities to young faculty and their undergraduate and graduate students by supporting advanced scientific research. The goals of the American Chemical Society Petroleum Research Fund are to support fundamental research in the petroleum field and develop the next generation of engineers and scientists through the support of advanced scientific education.

Dr. Bollas’ research project will explore aspects of Fischer-Tropsch Synthesis selectivity. The Fischer-Tropsch process is a collection of chemical reactions that provide a means of producing transportation fuels from carbon monoxide and hydrogen, a combination referred to as synthesis gas. This reaction also produces excess hydrocarbon products in addition to materials for fuel, so there remains a need to make this process more selective.

Through Dr. Bollas’ research, it may be possible to significantly improve the selectivity of this process to make the synthesis of fuel through Fisher-Tropsch more efficient and economical. Dr. Bollas and his research group plan to examine novel catalyst synthesis methods that enhance the selectivity of Fischer-Tropsch Synthesis (FTS) towards intermediate-chain length hydrocarbons, particularly synthetic gasoline.

The benefits of making Fischer-Tropsch a more efficient and less centralized process are energy independence and security. In addition, the vast unexploited resources of natural gas found recently in the US make natural gas a major source for energy and fuels production. Dr. Bollas’ new experimental work will provide the capability to expand research exploring alternative fuels and efficient processes at the CBE Department and in the Center for Clean Energy Engineering.

Dr. Bollas is a process design expert and winner of the prestigious NSF CAREER Award and the ACS PRF DNI Award. His research focuses on biomass pyrolysis, coal and biomass to liquids, Fischer-Tropsch synthesis, chemical-looping combustion, and waste to energy processes.

Amanda Card Receives 2013 Outstanding Student Women Academic Achievement Award

Modified from original version with permission from Momentum, a School of Engineering electronic publication.

Chemical Engineering senior Amanda Card received the 2013 Outstanding Student Women Academic Achievement Award for an undergraduate. She has maintained a cumulative GPA of 4.0 while devoting significant time to outreach activities, scholarly research, and leadership duties within the Society of Women Engineers (SWE).

Amanda has served as Collegiate Section President, Conference Committee Chair and Secretary of UConn’s SWE chapter, and worked as a STEM instructor for eighth grade students from underserved communities who participate in UConn’s Pre-Engineering Program (PEP). Amanda’s undergraduate research, overseen by Dr. Leslie Shor, has involved contributions to the development of an optical method that measures diffusivity through hydrogel-filled microfluidic capillaries. She has also interned with both Unilever and Saint-Gobain. Amanda is excited to begin her career with MPR Associates, Inc. in Alexandria, VA following graduation.

CBE Launching Revised Capstone Senior Design Program

By Jayna Miller

The Chemical & Biomolecular Engineering (CBE) Department is pleased to announce the launch of a revised Capstone Senior Design program this fall 2013. In this new format, each faculty member will be advising one or two capstone design projects over the entire academic year.

Prof. Leslie Shor, building on the recent successes of Prof. Dan Burkey in formulating this new format, will be leading the effort for the department. Professor Shor is a Northeast Utilities Assistant Professor of Environmental Engineering Education, and currently leads the Engineered Microhabitats research group.

Professor Shor will be chairing a “Capstone Design Governance Committee,” which will propose guidelines for Capstone Design projects, create templates for project descriptions and general project criteria, and work with faculty to ensure proposed projects meet the criteria. Working with Burkey and Prof. George Bollas, the committee will also create milestone and evaluation rubrics for the faculty and students to follow, and produce an “example design projects catalog,” which can be used to recruit industry sponsors. The overarching goal is to help the department provide the best design experience for students and our industry partners.

In Capstone Design, our seniors are mentored by chemical engineering faculty and industry sponsors as they apply engineering fundamentals and tools to solve practical engineering problems. Students use this experience to develop teamwork and communication skills as they tackle their open-ended, real-world challenges. They learn about the principles and practices of design, setting priorities, project management, ethical and economic decision making, intellectual property, oral and written communication, all as they evaluate their design from a technical, economic, safety, and environmental perspective.

The department is actively seeking industry partners to propose and support a student project. For more information, please visit: http://www.cbe.engr.uconn.edu/undergraduate-program/capstone-design and learn how to join our team.

UConn Engineering Honors John (Jack) Prior

During a gala event on May 2 at the Storrs campus, the School of Engineering honored 10 exceptional alumni and friends as 2013 inductees into the UConn Academy of Distinguished Engineers. Nearly 100 attendees helped to honor the new inductees, each of whom spoke of the profound influence of UConn Engineering in shaping their careers. One inductee was an alumnus of the Chemical Engineering department, John Prior.

During a gala event on May 2 at the Storrs campus, the School of Engineering honored 10 exceptional alumni and friends as 2013 inductees into the UConn Academy of Distinguished Engineers. Nearly 100 attendees helped to honor the new inductees, each of whom spoke of the profound influence of UConn Engineering in shaping their careers. One inductee was an alumnus of the Chemical Engineering department, John Prior.

John (Jack) Prior graduated from UConn in 1986 with a B.S. in Chemical Engineering, and then went on to earn a doctorate of science (Sc.D.) in Chemical Engineering from MIT, focusing his research on monitoring and controlling bioreactors for the production of biopharmaceuticals.

Jack’s current position is Senior Director for Bioprocess Engineering at Genzyme, where he oversees a team of 14 engineers responsible for improving the manufacturing processes for these and other biopharmaceutical compounds that can be incredibly challenging to produce.

Jack’s work often places him in the “front lines” in addressing critical challenges. For example, he led company efforts to identify and correct the cause of a Thymoglobulin production challenge at the company’s facility in France in 2007. His efforts enabled patients to continue to receive this life-saving therapy. In 2008, he led efforts to understanding and address product comparability issues that had previously delayed the introduction of adult treatments for Pompe’s disease in the US. Jack also played a key role the troubleshooting effort surrounding a viral contamination episode the company experienced in 2009.

In addition to Jack’s important management and manufacturing technology development role in the biopharmaceutical industry, he has given back to UConn directly by serving as a member of the Chemical Engineering Industrial Advisory Board since 2006. In this capacity, he generously gives his time to provide critique, guidance, and support to the Chemical Engineering program. The CBE department would like to extend its congratulations to Jack Prior for his induction into the UConn Academy of Distinguished Engineers.

GOALI Award for Interdisciplinary Team

Materials Science & Engineering (MSE) professor Dr. Radenka Maric, in close collaboration with MSE Industrial Advisory Board member Armand Halter and Dr. William Mustain (Chemical & Biomolecular Engineering), has received a prestigious, $423,000 National Science Foundation “Grant Opportunities for Academic Liaison with Industry” (GOALI) award.

Materials Science & Engineering (MSE) professor Dr. Radenka Maric, in close collaboration with MSE Industrial Advisory Board member Armand Halter and Dr. William Mustain (Chemical & Biomolecular Engineering), has received a prestigious, $423,000 National Science Foundation “Grant Opportunities for Academic Liaison with Industry” (GOALI) award.

The GOALI award seeks to promote collaboration between universities and industry by funding research projects that operate across this divide. Such projects provide academic researchers and industry practitioners the opportunity to better understand and bridge their different approaches, and to more rapidly move research from the lab to commercial markets.

The team’s project is entitled “GOALI: One Step Direct Deposition of Durable Cathode for High Temperature Proton Exchange Membrane Fuel Cell (PEMFC).” The importance of the proposed research lies in its position at the nexus of processing and microstructure with the activity, stability and utilization of catalysts using High Temperature Proton Exchange Membranes (HT-PEMFC).

Dr. Maric, who will lead the project as principal investigator, is a Connecticut Clean Energy Fund Professor of Sustainable Energy at UConn. Her research expertise lies in the area of novel materials for high temperature fuel cells, and she is the recipient of many prestigious awards. Dr. Maric was recently named a 2013 “Women of Innovation” Finalist in Research and Leadership by the Connecticut Technology Council. Read more about her research here.

Mr. Halter is the Vice President of Applied Sciences at Sonalysts, Inc., where his work includes the development of materials for alternative energy sources. Dr. Mustain is Associate Department Head of CBE.

Commencement 2013

Forty-nine students graduated with their B.S. in chemical engineering in a commencement exercise held on Saturday, May 11th at Gampel Pavilion on the Storrs campus. Kelsey Boch, who graduated with a double major in chemical engineering and molecular and cell biology, served as the student commencement speaker, and challenged students to take the paths less travelled, forge their own trails, and define success on their own terms. In the fall, Kelsey will start the next step in her academic journey when she starts medical school. Chemical engineering senior Amanda Card served as one of two ceremonial banner carriers in the processional, an honor usually reserved for the student or students with the highest GPA in the school of engineering. Amanda graduated with a perfect 4.0 GPA in her four years in the School of Engineering, and will join an energy and sustainability consulting firm in the Washington, D.C. area in the fall. Senior Christine Nykyforchyn performed a stunning a cappella version of the national anthem to lead off the ceremonies, and will start her studies in the graduate biomedical engineering program at Boston University in the fall. All in all, seniors in the class of 2013 will join some of the biggest and best companies in Connecticut and beyond, and will enroll in some of the most prestigious graduate programs in the nation, including MIT, Columbia, The University of Texas at Austin, Purdue, and Boston University.

The faculty and staff of the Chemical and Biomolecular Engineering department wish the Class of 2013 all the best as they move into the next chapter of their lives!

CBE Professor Received The Technology Innovation and Development Award

Republished with permission of Momentum,

a School of Engineering electronic publication.

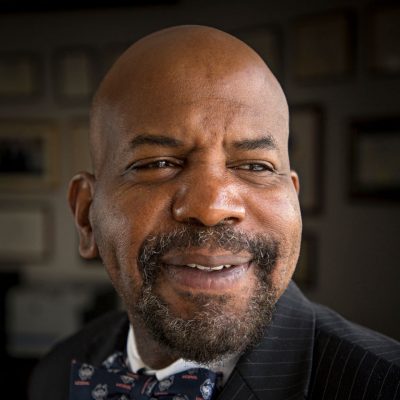

Dr. Cato Laurencin, M.D., Ph.D., was presented the Technology Innovation and Development Award from the Society for Biomaterials. Dr. Laurencin is CEO of the Connecticut Institute for Clinical and Translational Science, Director of the Institute for Regenerative Engineering, the Van Dusen Endowed Chair in Academic Medicine and a professor of Chemical & Biomolecular Engineering. The award recognizes an individual or team who provided key scientific and technical innovation and leadership in a novel product in which biomaterials played an important and enabling role. For more than three decades, Dr. Laurencin has conducted research studies on biomaterials for musculoskeletal tissue engineering, nanotechnology, and drug delivery. He notes that he was influenced by his Ph.D. mentor, Dr. Robert Langer, an Institution Professor at MIT. Read more about Dr. Laurencin here.

Dr. Cato Laurencin, M.D., Ph.D., was presented the Technology Innovation and Development Award from the Society for Biomaterials. Dr. Laurencin is CEO of the Connecticut Institute for Clinical and Translational Science, Director of the Institute for Regenerative Engineering, the Van Dusen Endowed Chair in Academic Medicine and a professor of Chemical & Biomolecular Engineering. The award recognizes an individual or team who provided key scientific and technical innovation and leadership in a novel product in which biomaterials played an important and enabling role. For more than three decades, Dr. Laurencin has conducted research studies on biomaterials for musculoskeletal tissue engineering, nanotechnology, and drug delivery. He notes that he was influenced by his Ph.D. mentor, Dr. Robert Langer, an Institution Professor at MIT. Read more about Dr. Laurencin here.

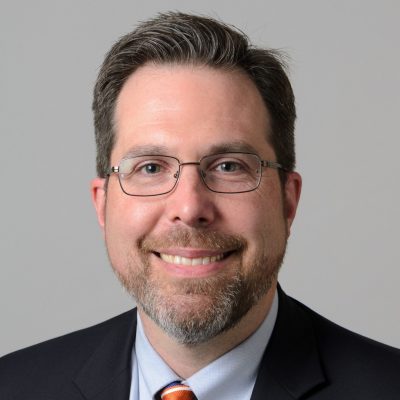

Dr. Daniel Burkey Promoted to Associate Dean for Undergraduate Education and Diversity

Effective July 1, 2013, Dr. Daniel Burkey will assume the position of Associate Dean for Undergraduate Education and Diversity.

Effective July 1, 2013, Dr. Daniel Burkey will assume the position of Associate Dean for Undergraduate Education and Diversity.

For the past three years, Dr. Burkey has been the Chemical & Biomolecular Engineering (CBE) Associate Department Head, as well as Associate Professor-in-Residence of Chemical Engineering. During his time with CBE, he examined and revised the undergraduate Chemical Engineering curriculum to better meet the rapidly changing demands of the current job market, specifically focusing on the senior laboratory and senior design courses. Improvements have included the implementation of new experiments, which reflect the demands, equipment, and techniques of the profession, and partnership with local industries to engage students with real-world problems. He also oversaw the renovation of the Chemical Engineering undergraduate laboratory. Students voted Dr. Burkey AIChE Teacher of the Year for both the 2010-2011 and 2011-2012 academic years. CBE thanks Dr. Burkey for his contributions and congratulates him on his new position within the School of Engineering.

Dr. William Mustain Promoted to Associate Department Head

The Chemical and Biomolecular Engineering Department is pleased to announce that, as of July 1, 2013, Dr. William Mustain will be the Associate Department Head of CBE. His responsibilities will include chairing the department’s Undergraduate Committee, serving as the point of contact for students, families, and visitors to CBE, and working with the Department Head, faculty, and staff to ensure all of CBEs needs and duties are addressed to the greatest extent possible. In addition, Dr. Mustain will be promoted to Associate Professor in August.

The Chemical and Biomolecular Engineering Department is pleased to announce that, as of July 1, 2013, Dr. William Mustain will be the Associate Department Head of CBE. His responsibilities will include chairing the department’s Undergraduate Committee, serving as the point of contact for students, families, and visitors to CBE, and working with the Department Head, faculty, and staff to ensure all of CBEs needs and duties are addressed to the greatest extent possible. In addition, Dr. Mustain will be promoted to Associate Professor in August.

In the past, Dr. Mustain has occupied various leadership positions within CBE, most notably as Chair of the Graduate Committee from 2009-2012 as well as the head of the department’s ABET accreditation process. Academically, Dr. Mustain’s electrochemistry research group investigates the development of novel electrocatalyst materials for energy conversion and storage, and most recently his lab was recognized for developing a promising, high- performance fuel cell catalyst. Dr. Mustain came to UConn in 2008, following a Postdoctoral Fellowship at the Georgia Institute of Technology. He received his Ph.D. from the Illinois Institute of Technology in 2006.

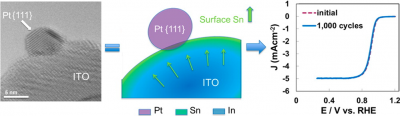

Mustain Group Develops High Performance Fuel Cell Catalyst

CBE Professor William Mustain and Ph.D. candidate Ying Liu have reported, in a paper published in the February issue of the Journal of the American Chemical Society (J. Am. Chem. Soc., 2013, 135(2), pp 530–533; DOI: 10.1021/ja307635r), that a new catalyst material using tin-doped indium oxide (ITO) nanoparticles (NPs) as a high stability non-carbon support for platinum (Pt) nanoparticles has great potential as a next-generation catalyst for the oxygen reduction reaction (ORR) in proton exchange membrane (PEM) fuel cells. As Liu and Mustain explain in their paper: “Sn was employed as the In2O3 dopant to exploit the strong interaction between Sn and Pt that was previously reported to enhance the activity of Pt on Pt/SnO2, while concomitantly avoiding the intrinsic stability limitations of SnO2 and leveraging the high stability of bulk In2O3 at ORR relevant potentials” This Pt/ITO catalyst showed mass activity that far surpassed the 2015 U.S. Department of Energy goal for Pt mass activity, and the stability of the Pt/ITO was remarkable under harsh conditions. In the future, Dr. Mustain and Ms. Liu will continue to improve the long-term stability of Pt/ITO and investigate its performance in PEM fuel cell stacks.

UConn Places First in AIChE “ChemE Car” Poster Competition

On April 13th and 14th, thirteen UConn Chemical Engineering students took part in the American Institute of Chemical Engineers (AIChE) Regional Conference at UMass-Amherst.

While at the conference, the students participated in AIChE’s ChemE Car competition. This competition challenges students to build a car that can travel between 15 and 30 meters, carrying anywhere between 0 and 500 grams. Students are not told the exact numbers until the day of the competition, at which time they are allowed to make minor adjustments to suit the requirements. The competition’s rules stipulate that the car must be autonomous, powered by chemical reaction, and without mechanical or electrical brakes. In addition to the car, each group creates a poster explaining their car—the chemical reaction that powers it, stopping mechanism, safety features, design, circuitry, and special features. The UConn team, advised by Dr. William Mustain, placed first of nine teams in this poster competition.

This was the first time UConn has sent a car to compete at the conference. Though the UConn group’s car, named “Harold Chegger,” did not place in the competition, the team is all very pleased with its performance. The group is looking forward to refining the car for competition next year.

In addition to participating in the competition, the group was invited by Governor Malloy to present their car at the Next Gen CT news conference, held on April 11th. The event highlighted the growing support among industry, legislature, faculty, and students for the Next Generation Connecticut initiative. This proposal would support UConn’s expansion in the STEM (science, technology, math, and engineering) disciplines.

Connect to UConn Chemical Engineering with LinkedIn

It is now possible to connect with the UConn Chemical & Biomolecular Engineering Department using the popular professional networking website, LinkedIn. This will be a useful tool for university professors, members of academia, alumni, graduate and undergraduate students, and industry and public sector partners alike, because a LinkedIn connection with Chemical Engineering gives professionals access to a wide range of information and services. By connecting with CBE, members will have access to departmental jobs, news, and updates, as well as general career advice, job opportunities, and professional connections. Follow the link to access the membership page!

UConn Professor’s Patented Technique Key to New Solar Power Technology

- February 4, 2013, UConn Today

- By: Colin Poitras

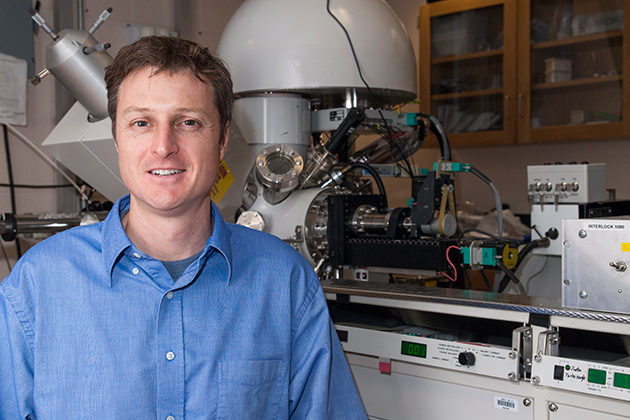

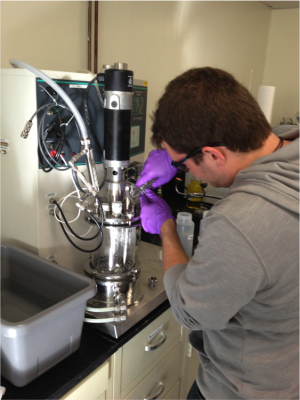

Brian Willis, associate professor of chemical, materials, and biomolecular engineering, in his lab, with an X-ray photoelectron spectrometer. (Sean Flynn/UConn Photo)

A novel fabrication technique developed by UConn engineering professor Brian Willis could provide the breakthrough technology scientists have been looking for to vastly improve today’s solar energy systems.

For years, scientists have studied the potential benefits of a new branch of solar energy technology that relies on incredibly small nanosized antenna arrays that are theoretically capable of harvesting more than 70 percent of the sun’s electromagnetic radiation and simultaneously converting it into usable electric power.

The technology would be a vast improvement over the silicon solar panels in widespread use today. Even the best silicon panels collect only about 20 percent of available solar radiation, and separate mechanisms are needed to convert the stored energy to usable electricity for the commercial power grid. The panels’ limited efficiency and expensive development costs have been two of the biggest barriers to the widespread adoption of solar power as a practical replacement for traditional fossil fuels.

But while nanosized antennas have shown promise in theory, scientists have lacked the technology required to construct and test them. The fabrication process is immensely challenging. The nano-antennas – known as “rectennas” because of their ability to both absorb and rectify solar energy from alternating current to direct current – must be capable of operating at the speed of visible light and be built in such a way that their core pair of electrodes is a mere 1 or 2 nanometers apart, a distance of approximately one millionth of a millimeter, or 30,000 times smaller than the diameter of human hair.

“This new technology could get us over the hump and make solar energy cost-competitive with fossil fuels. ”

The potential breakthrough lies in a novel fabrication process called selective area atomic layer deposition (ALD) that was developed by Willis, an associate professor of chemical, materials, and biomolecular engineering and the previous director of UConn’s Chemical Engineering Program. Willis joined UConn in 2008 as part of an eminent faculty hiring initiative that brought an elite team of leaders in sustainable energy technology to the University. Willis developed the ALD process while teaching at the University of Delaware, and patented the technique in 2011.

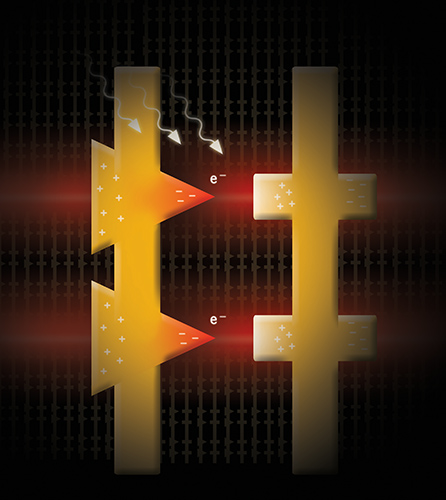

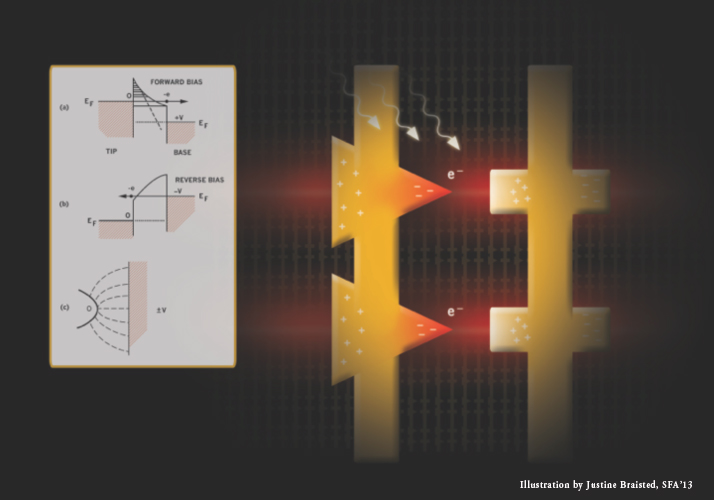

Illustration of a working nanosized optical rectifying antenna or rectenna. (Image courtesy of Brian Willis)

It is through atomic layer deposition that scientists can finally fabricate a working rectenna device. In a rectenna device, one of the two interior electrodes must have a sharp tip, similar to the point of a triangle. The secret is getting the tip of that electrode within one or two nanometers of the opposite electrode, something similar to holding the point of a needle to the plane of a wall. Before the advent of ALD, existing lithographic fabrication techniques had been unable to create such a small space within a working electrical diode. Using sophisticated electronic equipment such as electron guns, the closest scientists could get was about 10 times the required separation. Through atomic layer deposition, Willis has shown he is able to precisely coat the tip of the rectenna with layers of individual copper atoms until a gap of about 1.5 nanometers is achieved. The process is self-limiting and stops at 1.5 nanometer separation.

The size of the gap is critical because it creates an ultra-fast tunnel junction between the rectenna’s two electrodes, allowing a maximum transfer of electricity. The nanosized gap gives energized electrons on the rectenna just enough time to tunnel to the opposite electrode before their electrical current reverses and they try to go back. The triangular tip of the rectenna makes it hard for the electrons to reverse direction, thus capturing the energy and rectifying it to a unidirectional current.

Impressively, the rectennas, because of their incredibly small and fast tunnel diodes, are capable of converting solar radiation in the infrared region through the extremely fast and short wavelengths of visible light – something that has never been accomplished before. Silicon solar panels, by comparison, have a single band gap which, loosely speaking, allows the panel to convert electromagnetic radiation efficiently at only one small portion of the solar spectrum. The rectenna devices don’t rely on a band gap and may be tuned to harvest light over the whole solar spectrum, creating maximum efficiency.

The federal government has taken notice of Willis’s work. Willis and a team of scientists from Penn State Altoona along with SciTech Associates Holdings Inc., a private research and development company based in State College, Pa., recently received a $650,000, three-year grant from the National Science Foundation to fabricate rectennas and search for ways to maximize their performance.

Brian Willis holds a rectenna device. (Sean Flynn/UConn Photo)

The atomic layer deposition process is favored by science and industry because it is simple, easily reproducible, and scalable for mass production. Willis says the chemical process is already used by companies such as Intel for microelectronics, and is particularly applicable for precise, homogenous coatings for nanostructures, nanowires, nanotubes, and for use in the next generation of high-performing semi-conductors and transistors.

Willis says the method being used to fabricate rectennas also can be applied to other areas, including enhancing current photovoltaics (the conversion of photo energy to electrical energy), thermoelectrics, infrared sensing and imaging, and chemical sensors.

A 2011 seed grant from UConn’s Center for Clean Energy Engineering allowed Willis to fabricate a prototype rectenna and gather preliminary data using ALD that was instrumental in securing the NSF grant, Willis says.

Over the next year, Willis and his collaborators in Pennsylvania plan to build prototype rectennas and begin testing their efficiency. Willis compares the process to tuning in a station on a radio.

“We’ve already made a first version of the device,” says Willis. “Now we’re looking for ways to modify the rectenna so it tunes into frequencies better. I compare it to the days when televisions relied on rabbit ear antennas for reception. Everything was a static blur until you moved the antenna around and saw the ghost of an image. Then you kept moving it around until the image was clearer. That’s what we’re looking for, that ghost of an image. Once we have that, we can work on making it more robust and repeatable.”

Willis says finding that magic point where a rectenna picks up maximum solar energy and rectifies it into electrical power will be the champagne-popping, “ah-ha” moment of the project.

“To capture the visible light frequencies, the rectenna have to get smaller than anything we’ve ever made before, so we’re really pushing the limits of what we can do,” says Willis. “And the tunnel junctions have to operate at the speed of visible light, so we’re pushing down to these really high speeds to the point where the question becomes ‘Can these devices really function at this level?’ Theoretically we know it is possible, but we won’t know for sure until we make and test this device.”

Professor Anson Ma Honored With Prestigious NSF CAREER Award

Professor Anson Ma of the Chemical Engineering Program has received the CAREER award (#1253613) from the National Science Foundation (NSF). The Faculty Early Career Development (CAREER) Program is NSF’s most prestigious award for junior faculty, reserved for those who embody the role of “teacher-scholars” by seamlessly integrating outstanding research and excellent education. Ma’s award is given by the Fluid Dynamics Program of the Chemical, Bioengineering, Environmental, and Transport Systems (CBET) Division. The award provides $400,000 in research funding support over a period of 5 years.

Professor Anson Ma of the Chemical Engineering Program has received the CAREER award (#1253613) from the National Science Foundation (NSF). The Faculty Early Career Development (CAREER) Program is NSF’s most prestigious award for junior faculty, reserved for those who embody the role of “teacher-scholars” by seamlessly integrating outstanding research and excellent education. Ma’s award is given by the Fluid Dynamics Program of the Chemical, Bioengineering, Environmental, and Transport Systems (CBET) Division. The award provides $400,000 in research funding support over a period of 5 years.

The title of Dr. Ma’s winning proposal is “Understanding the interfacial rheology of carbon nanotubes at the fluid-fluid interfaces for creating ultra-stable emulsions and microcapsules”. Particles of appropriate size and wetability are known to stabilize emulsions, but the effect of particle shape remains largely unexplored. Dr. Ma and team propose that the shape matters and that particle shape could be the missing key to unlock the full potential of using particles to stabilize emulsions. To this end, Dr. Ma and his team will investigate the flow behavior of CNTs at fluid-fluid interfaces using carbon nanotubes as a model system. The success of the proposed research will offer a general and yet relatively simple strategy (i.e., by exploiting particle shape) to improve the stability of emulsions, prolonging the shelf life of widely used pharmaceutical, agricultural, and personal care products. The findings may also revolutionize the use of nanoparticles for enhanced oil recovery, essential to ensuring national energy independence and addressing the world’s energy challenge.

Further, Dr. Ma has a long-term vision that the asymmetry of the interface may offer an effective way to assemble nanoparticles into ordered structures and to create next-generation metamaterials. Metamaterials are hierarchically ordered structures that can be used in cloaking devices and light-based circuits that may ultimately outperform electron-based computers in terms of speed, power consumption, and costs. The proposed research will be integrated with educational and outreach activities at all levels to maximize its impact. Dr. Ma and his team will use culinary foams and emulsions (e.g., cappuccino foam, ice cream mix) as the theme to introduce basic scientific concepts to the younger generation and the local community.

Dr. Ma, who earned his Ph.D. from the University of Cambridge in the UK, joined UConn in August 2011 following a two-year appointment as the J. Evans Attwell-Welch Postdoctoral Fellow at Rice University. He has a dual appointment in the Polymer Program at the Institute of Materials Science (IMS). He recently received the Distinguished Young Rheologist Award from TA Instruments, which recognizes young faculty members who show exceptional promise in the field of rheology. Prior to that, he received the National Science Foundation Early Concept Grant for Exploration Research (EAGER) award, which focuses on investigating the use of nanoparticles in the delivery of cancer drugs.

UConn Partners with Penn State Altoona in Groundbreaking Project on Solar Power Technology

The University of Connecticut has partnered with Penn State Altoona in a collaborative research initiative, supported by a three-year, $650,000 grant from the National Science Foundation. The project is entitled “Electro-optical studies of nanoscale, geometrically asymmetric tunnel junctions for collection and rectification of light from infrared through visible” and will study the physics of a device, called a “rectenna,” that has the potential to dramatically advance solar power technology.

The research team includes UConn’s Dr. Brian Willis of Chemical Engineering; Drs. Gary Weisel, Brock Weiss and Darin Zimmerman (Altoona Physics); and emeritus professors Paul Cutler and Nicholas Miskovsky (Penn State Physics).

The rectenna will harness the visible portion of the solar spectrum, setting it apart from current technologies that are only capable of utilizing the infrared portion. The rectenna will comprise a nanosized antenna and ultra-fast tunnel diodes that collect and rectify solar radiation from infrared to visible. To manufacture such a device, the team developed a process called selective atomic layer deposition. This process makes the fabrication of arrays of thousands of nanoscopic, geometrically asymmetric tunnel junctions possible for the first time. The progress made possible by this research endeavor may increase solar power conversion technology efficiency, reduce costs, and create new economic opportunities. The project will enfold research and educational opportunities for high school, undergraduate and graduate students.

Professor Ma Received the “Distinguished Young Rheologist Award” from TA Instruments

Dr. Anson Ma of the Chemical Engineering Program has been chosen to receive the “Distinguished Young Rheologist Award” from TA Instruments. The decision was made by a panel comprising some of the most established and respected scientists in the field of rheology. Dr. Ma and his research team will receive an equipment grant for a new rheometer valued at $50,000.

Dr. Anson Ma of the Chemical Engineering Program has been chosen to receive the “Distinguished Young Rheologist Award” from TA Instruments. The decision was made by a panel comprising some of the most established and respected scientists in the field of rheology. Dr. Ma and his research team will receive an equipment grant for a new rheometer valued at $50,000.

Dr. Ma joined UConn in August 2011 with a dual appointment in the Polymer Program at the Institute of Materials Science. The mission of his lab, Complex Fluids Laboratory, is to understand the rheology and processing of complex fluids (e.g., foams, emulsions, polymers, and biological fluids). Current research interests in Dr. Ma’s lab involve (i) exploring the interfacial rheology of nanoparticle-laden interfaces for creating ultra-stable emulsions and microcapsules, and (ii) understanding the flow dynamics of nanoparticles in simulated blood flows for improved cancer treatment (currently sponsored by the National Science Foundation through NSFGRF and EAGER awards).

TA Instruments – a subsidiary of Waters Corporation (NYSE: WAT) – is a leading manufacturer of analytical instruments for thermal analysis, rheology, and microcalorimetry. The company is headquartered in New Castle, Delaware, USA, and has direct operations in 23 countries. TA Instruments established the “Distinguished Young Rheologist” award to recognize product innovation and research into new materials and applications that expand the field of rheology, and to help accelerate the research of new academics.

Chemical Engineering Well Represented at Annual AIChE Meeting 2012

UConn chemical engineering students shone at the American Institute of Chemical Engineers (AIChE) annual meeting held in Pittsburgh from October 26th to November 2nd. With Hurricane Sandy bearing down on the Eastern Seaboard, it was challenging to get everyone out to the conference in advance of the storm, and some faculty and students were unable to attend.

Despite the weather setbacks, during the undergraduate conference, which preceded the professional/academic portion of the conference, UConn’s AIChE student members performed admirably. Officers Breanne Muratori (chapter President) and Kimberly Dout (chapter Secretary) attended student leadership events, which they found to be informative and productive in terms of networking with fellow officers across the country.

Seven undergraduates participated in the undergraduate poster competition. Emily Anderson (‘12), advised by Dr. Leslie Shor, was awarded first place in the Environmental Science and Engineering division for her poster, “Impact of Hydrogel Content on Water Retention in Soil Micromodels.” Additionally, Breanne Muratori, advised by Dr. Jeff McCutcheon, gave an oral presentation entitled “Improving the Mechanical Properties of Activated Carbon Nanofiber Nonwovens.” It was one of only a handful of talks given by undergraduates at the meeting and reflects UConn AIChE’s dedication to better bridging the student section and the professional conference.

In celebration of their accomplishments, the UConn chemical engineering students and faculty held a dinner at the Bigelow Grille in Pittsburgh. A bonus of Hurricane Sandy’s grounding of the group in Pittsburgh was that it enabled the undergraduates to stay a few extra days and experience the larger professional conference, including the university hospitality suites. UConn’s hospitality suite was a great success, with over 300 alumni and friends in attendance.

New Research Awards

The Chemical & Biomolecular Engineering Program would like to recognize their respective faculty members who have recently been granted new funding initiatives.

Daniel Gage (Molecular and Cell Biology) and Leslie Shor, USDA/National Institute of Food and Agriculture, Microfluidic Studies of Signaling Between Rhizosphere Bacteria and their Predators, 2/12-2/14, $150,000.

Yu Lei, University of Connecticut Center for Science & Technology Commercialization, Naked Eye-based Standoff Detection of Explosives Using Novel Signal-Amplifying Nanocomposite and Hand-held UV Light, 8/12-12/13, $7,500.

Anson Ma, NSF, Understanding the Flow Dynamics and Transport of Nanoparticles in Simulated Tumor Blood Flows for Improved Cancer Treatment, 9/12-8/14, $150,000.

Jeffrey McCutcheon, NSF, Collaborative Research: Modified Reverse Osmosis Membranes for Forward and Pressure Retarded Osmosis, 8/12-7/15, $234,405.

Jeffrey McCutcheon, Solvay Specialty Polymers, Polymeric Membranes for Emerging Separation Processes, 1/12-4/13, $102,679.

Jeffrey McCutcheon, Chevron USA, Produced Water Treatment using Forward Osmosis; Phase 1: Membrane Performance Testing, 4/12-1/13, $45,000.

Mu-Ping Nieh, James Cole (Molecular and Cell Biology) and Douglas Adamson (Chemistry), NSF, MRI: Acquisition of a State-of-the-Art Small Angle X-Ray Scattering (SAXS) Instrument for Research and Education, 9/12-8/15, $568,398.

Richard Parnas and Tim Dowding (School of Business), University of Connecticut Center for Science & Technology Commercialization, Biomass Waste to Construction Board, 5/12-1/13, $40,840.

Ioulia Valla and Prabhakar Singh, Precision Combustion Inc., 13X Zeolite as Potential Molecular Sieve for Gas Phase Impurities Removal: Emphasis on the Characterization of the Zeolite, 7/12-7/12, $9,995.

Ioulia Valla and George Bollas, NSF, Turning Tars into Energy: Zeolites with Hierarchical Pore Structure for the Catalytic Cracking of Tars, 8/12-7/14, $188,698.

Yong Wang, NSF, CREATIV: Programming Materials via Biomolecular Engineering, 9/12-8/15, $400,000.

Professor Ma Received NSF EAGER Award

Dr. Anson Ma of the Chemical Engineering Program has recently received NSF EAGER award (#1250661) to understand the flow dynamics of nanoparticles in simulated blood flows. Nanoparticles show great promise in delivering anticancer drugs more directly to tumors, thereby reducing the toxic side effects to normal tissues. The passive accumulation of nanoparticles in tumors is due to the enhanced permeability and retention (EPR) effect, caused by the leaky nature of the tumor vasculature. In order to improve cancer treatment, there is an urgent need to understand the detailed mechanism of EPR.

Dr. Anson Ma of the Chemical Engineering Program has recently received NSF EAGER award (#1250661) to understand the flow dynamics of nanoparticles in simulated blood flows. Nanoparticles show great promise in delivering anticancer drugs more directly to tumors, thereby reducing the toxic side effects to normal tissues. The passive accumulation of nanoparticles in tumors is due to the enhanced permeability and retention (EPR) effect, caused by the leaky nature of the tumor vasculature. In order to improve cancer treatment, there is an urgent need to understand the detailed mechanism of EPR.

Dr. Ma and his team will construct novel microfluidic devices that mimic blood bifurcation and leaky tumor blood vessels. The trajectory of nanoparticles in stimulated blood flows will then be characterized. The proposed research will strengthen our fundamental understanding of the EPR effect – the hallmark of passive targeted delivery of anticancer drugs. The success of the proposed research will also have far-reaching implications on the rational design of nanoparticles to allow more specific delivery of anticancer drug to tumors, thereby increasing patient comfort during cancer treatment and fulfilling a societal need.

New Bioreactor Experiment Debuts in Chemical Engineering Senior Lab

This fall, a new experiment on cell culture and scale-up is allowing seniors in the Chemical Engineering Program to gain hands-on experience with elements of bioprocess engineering. Thanks to a generous equipment donation from Alexion Pharmaceuticals (Cheshire, CT), students have the opportunity to utilize industry-standard equipment and learn firsthand the challenges of working with live cell cultures. This new experiment now serves as one of the anchor experiments in the rotation. Students spend three weeks getting a taste of the entire experience, including media preparation, sterilization techniques, small-scale batch culture, and scale up to the 2-L bioreactor. Once in the bioreactor, the students look at how various parameters, including glucose concentration, agitation rate, and temperature impact the growth kinetics of their model system, E. Coli, with an eye towards maximizing biomass production. This new experiment provides the opportunity to expose the numerous undergraduates who are interested in biochemical or bioprocess engineering to the fundamentals of industrial biotech processes.

CHEG Presents Distinguished Lecturer Edwin L. Thomas

DISTINGUISHED LECTURER

Edwin L. “Ned” Thomas

William and Stephanie Sick Dean,

George R. Brown School of Engineering Rice University

Thursday, October 25, 2012

Dodd Konover Auditorium

4:00 P.M.

INDISTINGUISHABLE FROM MAGIC?

A Perspective on Some Aspects of Materials Research in the Next Decade.

Multifunctional Materials: The Mighty Electron, the Cool Photon and the Lowly Phonon…

Problem Driven Research: Improving Sets of Properties.

Creating the Magic: Synthetic MetaMaterials. MetaMaterials blur the distinction and

bridge the regime in between engineered microstructured materials with their enhanced

properties of the traditional type and multicomponent structured devices that can display functionality (amplification, filtering, sensing, etc.). Such material systems open a whole new range of heretofore unimagined material system behaviors (e.g., cloaking).

Friday, October 26, 2012

Institute of Materials Science

Room 20

11:00 A.M.

New Ideas to Manipulate the Mechanical Behavior of Polymeric Materials – from Phonons to Ballistics to Shock

Several examples will be described including the design of structures for multispectral band gaps for elastic waves to alter the phonon density of states, the creation of block polymer and bicontinuous metal-carbon nanoframes for structures that are robust against ballistic projectiles and quasi-crystalline solid/fluid structures that can steer shock waves.

Edwin L. “Ned” Thomas is the William and Stephanie Sick Dean of the George R. Brown School of Engineering at Rice University. He holds joint appointments with the Department of Mechanical Engineering and Materials Science and Department of Chemical and Biomolecular Engineering, and frequently collaborates with faculty in the Richard E. Smalley Institute for Nanoscale Science and Technology.

Dr. Thomas joined Rice from MIT, where he was first the founder and director of the MIT Institute for Soldier Nanotechnology (2002-2006) and then the head of the Department of Materials Science and Engineering (2006-2011). Preceding his career at MIT, Thomas founded and co-directed the Institute for Interface Science and headed the Department of Polymer Science and Engineering at the University of Massachusetts.