Consider the complexity of a modern passenger airliner. An aircraft is a self-contained “system-of-systems,” consisting of a diverse assortment of interdependent subsystems and components working together. Electrical, hydraulic, flight control, fuel handling, cabin pressurization, and engine systems are all crucial parts of a functional aircraft, each with their own constraints and requirements in addition to those of the aircraft as a whole.

Consider the complexity of a modern passenger airliner. An aircraft is a self-contained “system-of-systems,” consisting of a diverse assortment of interdependent subsystems and components working together. Electrical, hydraulic, flight control, fuel handling, cabin pressurization, and engine systems are all crucial parts of a functional aircraft, each with their own constraints and requirements in addition to those of the aircraft as a whole.

The complexity of engineering interconnected systems like aircrafts — or, for that matter, power plants, smart buildings, and modern manufacturing facilities — has led many industries to migrate toward formalized systems engineering, considering large systems holistically.

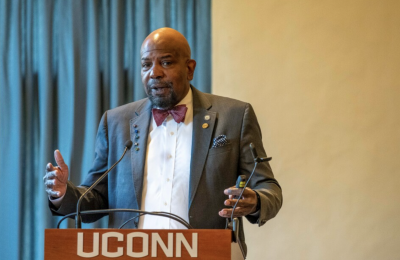

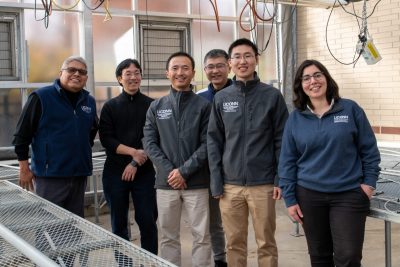

Led by George Bollas, the United Technologies Corporation Institute for Advanced Systems Engineering (UTC-IASE) has been solving these real-world problems for industry since 2013.

Bollas, who is a professor of chemical and biomolecular engineering in UConn’s School of Engineering, focuses his research on process design, simulation, optimization, control, and diagnostics. These research interests align seamlessly with the needs of industry partners like United Technologies Corporation.

Located in the University of Connecticut Tech Park’s Innovation Partnership Building, UTC-IASE is working on some of the most pressing challenges for businesses and research sponsors using innovative approaches to model-based systems engineering.

“We have converted it to something that is self-sustained and can work with United Technologies at many levels, but also engage other satellite industry partners, the state, and federal agencies to have a greater impact,” says Bollas.

Location, Location, Location

At UConn Tech Park, students from different departments and research groups in the School of Engineering who are working on different projects managed by the UTC-IASE can come together in a central location. Much like the complex operations the students are researching, their individual projects and skills all work together to make systems more efficient. Bollas says this allows for close collaboration and frequent discussion of what each individual group is tackling.

“For the first time we’re all in one place,” Bollas says. “To develop that culture for students, where they work next to each other, day and night, and all that good competition that comes out of it is very positive for the mindset and culture both at UConn and when these students go out in the workforce.”

“Industry often focuses on measurable outcomes, seeking means for producing their products better, faster, and at reduced cost. Awareness of these tangible impacts helps students understand the importance of their research”, says Bollas.

“In many cases, you know from the get-go that you are going to help a company solve a $10 million-a-year problem. It’s very exciting for the students to work on something that they understand has immediate value and impact on such a huge scale,” Bollas says.

Many of the students at the UTC-IASE go into careers with United Technology Corporation or other companies in the area of manufacturing, energy, aerospace, building, and robotics. The experience contributes to the preparation of graduate and undergraduate students for these careers as they learn to communicate with industry partners effectively and consistently.

“It’s a natural next step,” Bollas says. “It’s very helpful to know where they might be going, what they’re going to face in industry or academia.”

In addition to graduate research, UTC-IASE exposes UConn students to business professionals through a training program that was originally designed for employees of the corporation. Bollas says this training is critical, since the entire concept of systems engineering works to un-train students from thinking about problems in terms of their own specificity.

“In both research and training, we emphasize the concept of system-level thinking. One needs to understand what the entire system looks like – from architecture to requirements, design, commissioning, performance, and maintenance. This approach relies on thinking of the entire life-cycle of a system from design to decommissioning.”

To accomplish this, UTC-IASE offers training of professionals through a formal Graduate Certificate and a Master of Engineering program in Advanced Systems Engineering. These programs are offered to geographically dispersed professionals as well as students at UConn who are interested in developing a unique and valuable set of skills in the areas of model-based systems engineering of cyber-physical systems.

“We’re helping lifelong learning for the existing engineering workforce,” Bollas says. “We’re helping them understand what is the state-of-the-art, and some of the approaches and solutions to the problems they are dealing with in their everyday work. We call this integration of undergraduates, graduate students, and professional engineers a ‘talent eco-system’ that can produce and sustain a modern engineering workforce in the state and for the nation.”

Big Problems, Real Solutions

Bollas is currently collaborating with Collins Aerospace to improve fault detection and isolation methods. The advanced detection algorithms Bollas and his research team are developing are optimized for actively identifying faults during aircraft operation and helping to reduce false alarms. This project has already led to two patent applications filed jointly by UConn and Collins Aerospace.

“We’re transferring what we develop here at the university to actual industry environments, where we have access to all the data, constraints, requirements, and system-specific details. We do this through internships and sabbatical leaves, and this has really been a wonderful model for technology transfer,” Bollas says. “I’m not sure we’d be aware of the significance and limitations of our research if we weren’t working with a technology leader like UTC.”

Bollas again points to the importance of location, both in Connecticut and at Tech Park, to help the institute grow.

“There are so many opportunities generated for the institute just because we are located here,” Bollas says. “We’re working with several other Tech Park centers and their industry partners since they are more and more focused on ‘smart’ processes for manufacturing.”

Bollas is referring to a paradigm shift dubbed Industry 4.0 or “smart manufacturing,” which places emphasis on cyber-physical systems. Cyber-physical systems include physical machines controlled by computer-based algorithms that are deeply ingrained in the so-called Internet of Things. To remain competitive, companies like Collins Aerospace and Pratt & Whitney have been investing in the development of smart manufacturing technologies in their respective industries.

By having access to test beds at the Connecticut Center for Advanced Technology and the Pratt & Whitney Additive Manufacturing Center in the IPB, the UTC-IASE researchers working on smart manufacturing projects with the Department of Energy provide a better picture of how well their research, algorithms, and solutions will work when used in an industrial setting.

“Smart manufacturing solutions are sometimes easy on a computer, but when you actually have to deploy these advanced technologies, it’s very helpful to have test beds we can use right here at the Tech Park,” Bollas says.

Bollas says he is proud of laying a strong foundation for future growth through partnerships with industry and federal agencies on such a large scale. Moving forward, he has no doubt that the research collaborations taking place at UTC-IASE will continue to generate innovative, real-world solutions that help Connecticut and its industry partners grow.

October 2, 2019 – Anna Zarra Aldrich ’20 (CLAS), Office of the Vice President for Research

Warmest congratulations to Professor Kelly Burke on receiving a $2.7M R18 award from the National Institutes of Health to develop implantable drug‑delivery films designed to relieve pain after surgery. The project is funded under the NIH HEAL (Helping to End Addiction Long‑term) Initiative, which backs technologies and strategies that help prevent opioid misuse—in this case by reducing the need to prescribe opioids following common surgical procedures.

Warmest congratulations to Professor Kelly Burke on receiving a $2.7M R18 award from the National Institutes of Health to develop implantable drug‑delivery films designed to relieve pain after surgery. The project is funded under the NIH HEAL (Helping to End Addiction Long‑term) Initiative, which backs technologies and strategies that help prevent opioid misuse—in this case by reducing the need to prescribe opioids following common surgical procedures. Sharing exciting new research advancing smart sensor technologies to improve long-term monitoring of water and soil systems!

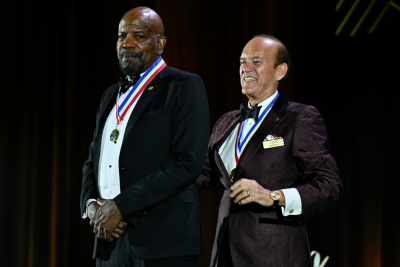

Sharing exciting new research advancing smart sensor technologies to improve long-term monitoring of water and soil systems! Congratulations to Sir Dr. Cato Laurencin on receiving the Bioactive Materials Lifetime Achievement Award, recognizing his pioneering contributions to biomaterials, regenerative engineering, and translational medicine.

Congratulations to Sir Dr. Cato Laurencin on receiving the Bioactive Materials Lifetime Achievement Award, recognizing his pioneering contributions to biomaterials, regenerative engineering, and translational medicine.

Warmest congratulations to our graduate students, Azeem Sarwar and Muhammad Faheem Hassan, on being selected as one of the five finalist teams for the UConn–Eversource Clean Energy & Sustainability Innovation Program!

Warmest congratulations to our graduate students, Azeem Sarwar and Muhammad Faheem Hassan, on being selected as one of the five finalist teams for the UConn–Eversource Clean Energy & Sustainability Innovation Program! We are extremely proud of our junior, Caitlin Noonan ’26, for being named a Goldwater Scholar!

We are extremely proud of our junior, Caitlin Noonan ’26, for being named a Goldwater Scholar!

President Radenka Maric (NAI Fellow, 2019) – A leader in sustainable energy, her pioneering work in materials and catalysts has advanced fuel cell technologies, energy storage, and electrochemical sensors, enabling high-performance clean energy solutions.

President Radenka Maric (NAI Fellow, 2019) – A leader in sustainable energy, her pioneering work in materials and catalysts has advanced fuel cell technologies, energy storage, and electrochemical sensors, enabling high-performance clean energy solutions. Prof. Cato Laurencin (NAI Fellow, 2013) – The first UConn faculty member to become an NAI Fellow and a trailblazer in regenerative engineering. His breakthroughs in nanotechnology, polymer chemistry, and tissue regeneration have earned him national honors, including the National Medal of Technology and Innovation.

Prof. Cato Laurencin (NAI Fellow, 2013) – The first UConn faculty member to become an NAI Fellow and a trailblazer in regenerative engineering. His breakthroughs in nanotechnology, polymer chemistry, and tissue regeneration have earned him national honors, including the National Medal of Technology and Innovation. Prof. Luyi Sun (NAI Fellow, 2021) – An expert in polymeric materials, ceramics, and composites, his research is driving innovation in packaging, energy, and catalysis, shaping next-generation materials for diverse applications.

Prof. Luyi Sun (NAI Fellow, 2021) – An expert in polymeric materials, ceramics, and composites, his research is driving innovation in packaging, energy, and catalysis, shaping next-generation materials for diverse applications. We are thrilled to share that our graduate student, Hasan Nikkhah, has received the Best Poster Award at the 2024 Foundations of Computer-Aided Process Design (FOCAPD) Conference for his work on seawater desalination. In collaboration with our undergraduate student Dev Barochia and under the guidance of Professor Burcu Beykal, Hasan presented their research, “Design and Optimization of a Multipurpose Zero Liquid Discharge Desalination Plant,” which introduces a novel approach to multicomponent seawater desalination with zero liquid discharge.

We are thrilled to share that our graduate student, Hasan Nikkhah, has received the Best Poster Award at the 2024 Foundations of Computer-Aided Process Design (FOCAPD) Conference for his work on seawater desalination. In collaboration with our undergraduate student Dev Barochia and under the guidance of Professor Burcu Beykal, Hasan presented their research, “Design and Optimization of a Multipurpose Zero Liquid Discharge Desalination Plant,” which introduces a novel approach to multicomponent seawater desalination with zero liquid discharge. Warmest congratulations to Professor Cato Laurencin, recipient of the 2025 Paul Terasaki Innovation Award! The Paul Terasaki Innovation Award honors individuals who have made outstanding and sustained contributions to biomedical innovation, recognizing those who not only advance research but also translate their discoveries into real-world medical solutions. Dr. Laurencin embodies this mission through his pioneering work in regenerative engineering, polymer science, and musculoskeletal repair and regeneration. His groundbreaking contributions include the invention of the Laurencin-Cooper ligament for regenerating the anterior cruciate ligament (ACL) and the development of engineered grafts for rotator cuff tendon repair and regeneration. His research has bridged fundamental science with transformative medical applications, impacting countless lives.

Warmest congratulations to Professor Cato Laurencin, recipient of the 2025 Paul Terasaki Innovation Award! The Paul Terasaki Innovation Award honors individuals who have made outstanding and sustained contributions to biomedical innovation, recognizing those who not only advance research but also translate their discoveries into real-world medical solutions. Dr. Laurencin embodies this mission through his pioneering work in regenerative engineering, polymer science, and musculoskeletal repair and regeneration. His groundbreaking contributions include the invention of the Laurencin-Cooper ligament for regenerating the anterior cruciate ligament (ACL) and the development of engineered grafts for rotator cuff tendon repair and regeneration. His research has bridged fundamental science with transformative medical applications, impacting countless lives. We proudly celebrate our faculty and students who have been recognized in the inaugural

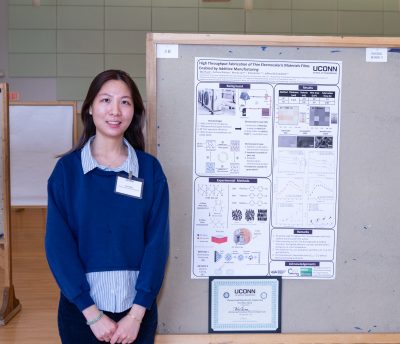

We proudly celebrate our faculty and students who have been recognized in the inaugural  We are proud to share that Professor Jeffrey McCutcheon has been awarded the AIChE FRI/Neil Yeoman Innovation Award by the AIChE Separations Division! This prestigious award recognizes Dr. McCutcheon’s pioneering research in additive manufacturing of thin film composite membranes, a significant advancement in membrane technology that has broad implications for separations science and industry. Dr. McCutcheon presented his groundbreaking work at the AIChE Annual Meeting Separations Division Plenary session last fall.

We are proud to share that Professor Jeffrey McCutcheon has been awarded the AIChE FRI/Neil Yeoman Innovation Award by the AIChE Separations Division! This prestigious award recognizes Dr. McCutcheon’s pioneering research in additive manufacturing of thin film composite membranes, a significant advancement in membrane technology that has broad implications for separations science and industry. Dr. McCutcheon presented his groundbreaking work at the AIChE Annual Meeting Separations Division Plenary session last fall. University

University

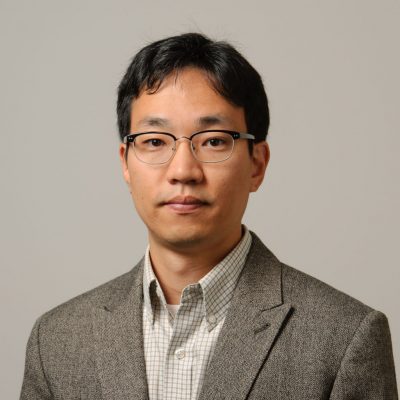

We’re thrilled to announce that Dr. Yongku Cho and his collaborator Dr. Jesse Rinehart from Yale University School of Medicine have been awarded $500,000 at the Tauopathy Challenge Workshop to investigate post-translational modifications in tau protein aggregates. These chemical changes, found in patients with Progressive Supranuclear Palsy (PSP) and Frontotemporal Dementias (FTDs), may increase tau aggregation and toxicity, both of which are critical contributors to these neurodegenerative diseases.

We’re thrilled to announce that Dr. Yongku Cho and his collaborator Dr. Jesse Rinehart from Yale University School of Medicine have been awarded $500,000 at the Tauopathy Challenge Workshop to investigate post-translational modifications in tau protein aggregates. These chemical changes, found in patients with Progressive Supranuclear Palsy (PSP) and Frontotemporal Dementias (FTDs), may increase tau aggregation and toxicity, both of which are critical contributors to these neurodegenerative diseases. We are thrilled to announce that our graduate student, Nicole Beauregard, has been awarded the NASA Connecticut Space Grant Consortium Graduate Student Fellowship. She will be working on integrating machine learning with evolutionary algorithms for the rapid discovery of high-performing metal-organic frameworks for gas adsorption.

We are thrilled to announce that our graduate student, Nicole Beauregard, has been awarded the NASA Connecticut Space Grant Consortium Graduate Student Fellowship. She will be working on integrating machine learning with evolutionary algorithms for the rapid discovery of high-performing metal-organic frameworks for gas adsorption. Warmest congratulations to Professor Cato Laurencin on his remarkable achievement of being inducted into the prestigious Plastics Hall of Fame. This honor recognizes his pioneering contributions to the field of regenerative engineering, where he has revolutionized the use of polymeric materials in developing cutting-edge medical devices, biologics, and pharmaceuticals. Prof. Laurencin’s groundbreaking work has transcended traditional boundaries, improving the lives of countless individuals worldwide.

Warmest congratulations to Professor Cato Laurencin on his remarkable achievement of being inducted into the prestigious Plastics Hall of Fame. This honor recognizes his pioneering contributions to the field of regenerative engineering, where he has revolutionized the use of polymeric materials in developing cutting-edge medical devices, biologics, and pharmaceuticals. Prof. Laurencin’s groundbreaking work has transcended traditional boundaries, improving the lives of countless individuals worldwide.

Warmest congratulations to Alanna Gado for being awarded the Graduate Research Fellowship sponsored by the

Warmest congratulations to Alanna Gado for being awarded the Graduate Research Fellowship sponsored by the  In the latest 2023 UConn Research Annual Report, the exceptional contributions of four distinguished faculty members take center stage. President Radenka Maric, along with esteemed professors Kelly Burke, Xiao-Dong Zhou, and Cato Laurencin, have been featured for their groundbreaking work spanning the realms of sustainability, energy, health, medicine, and community development. The report underscores the significant impact of their research, showcasing their commitment to advancing knowledge and addressing critical issues that resonate across diverse fields.

In the latest 2023 UConn Research Annual Report, the exceptional contributions of four distinguished faculty members take center stage. President Radenka Maric, along with esteemed professors Kelly Burke, Xiao-Dong Zhou, and Cato Laurencin, have been featured for their groundbreaking work spanning the realms of sustainability, energy, health, medicine, and community development. The report underscores the significant impact of their research, showcasing their commitment to advancing knowledge and addressing critical issues that resonate across diverse fields.

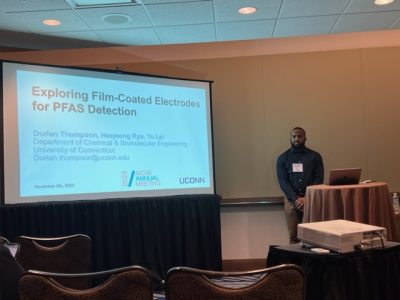

Warmest congratulations to Dorian Thompson for an outstanding achievement—securing the 3rd place in the Graduate Student Competition in Sensors at the AIChE Annual Meeting! Dorian works on PFAS detection under the advising of Professor Yu Lei.

Warmest congratulations to Dorian Thompson for an outstanding achievement—securing the 3rd place in the Graduate Student Competition in Sensors at the AIChE Annual Meeting! Dorian works on PFAS detection under the advising of Professor Yu Lei.

A newly awarded $2.5M

A newly awarded $2.5M Laron Burrows, making remarkable strides in environmental innovation. His groundbreaking work focuses on cleaning up one of the world’s dirtiest chemical processes, ammonia production. Along with Prof.

Laron Burrows, making remarkable strides in environmental innovation. His groundbreaking work focuses on cleaning up one of the world’s dirtiest chemical processes, ammonia production. Along with Prof.  C

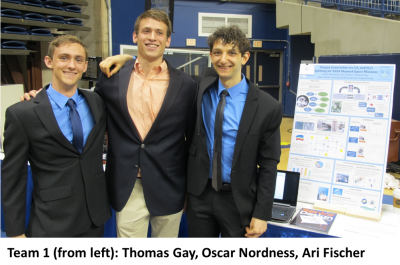

C May 1, 2015 marked the School of Engineering’s much anticipated Senior Design Day. The Department of Chemical & Biomolecular Engineering showcased the projects of 13 teams at the event, a school-wide poster competition held on the floor of the Gampel Pavilion arena.

May 1, 2015 marked the School of Engineering’s much anticipated Senior Design Day. The Department of Chemical & Biomolecular Engineering showcased the projects of 13 teams at the event, a school-wide poster competition held on the floor of the Gampel Pavilion arena. This year’s assortment of projects varied from inventing a human habitat on Mars, to designing wastewater treatments for Unilever. Visitors were even treated to samples of sugar-reduced ice cream developed by a student team for UConn’s Dairy Bar. The following teams earned the highest scores:

This year’s assortment of projects varied from inventing a human habitat on Mars, to designing wastewater treatments for Unilever. Visitors were even treated to samples of sugar-reduced ice cream developed by a student team for UConn’s Dairy Bar. The following teams earned the highest scores:

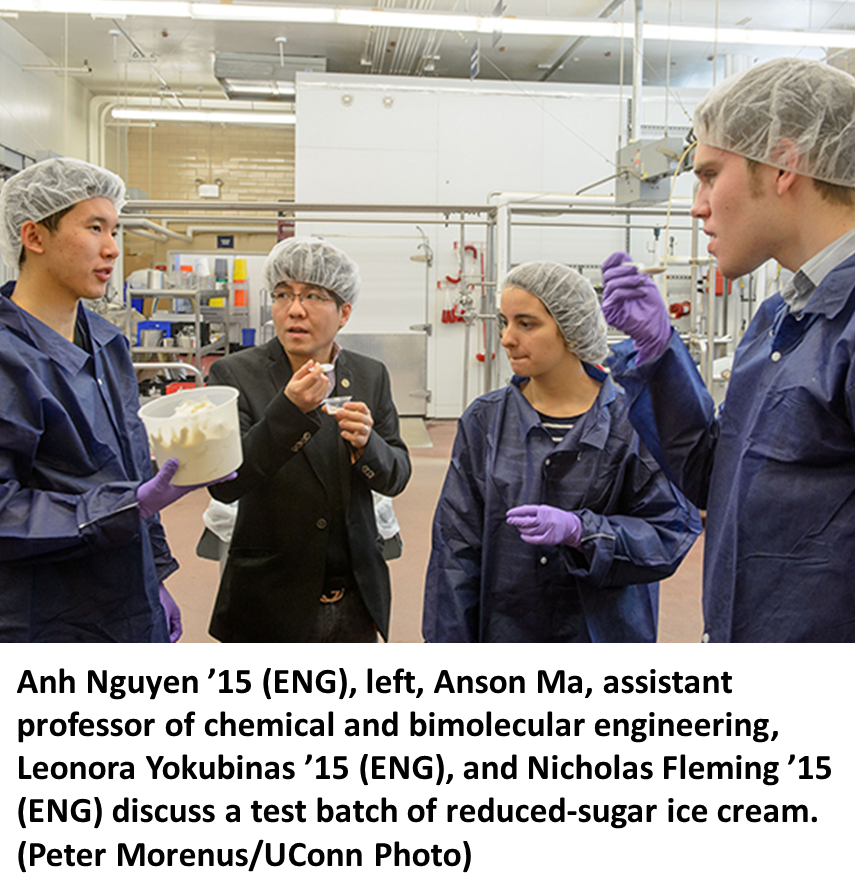

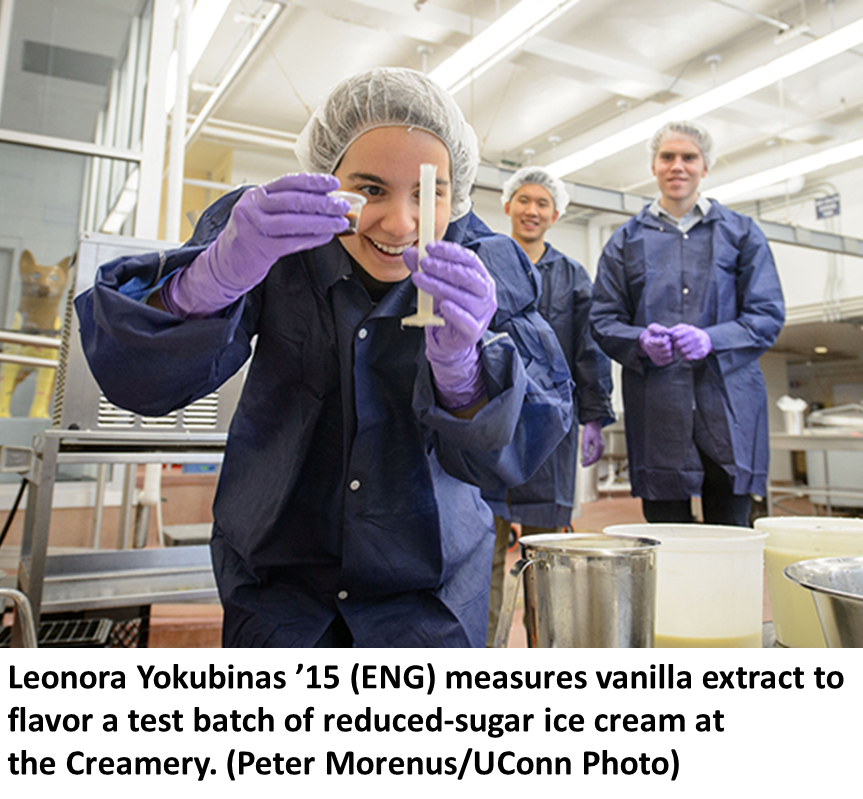

What happens when you mix UConn’s renowned Creamery and its top-notch Chemical Engineering department? If things go right, you get an ice cream that forgoes traditional sugar, but still earns a place along with the famously delicious ice creams at the Dairy Bar.

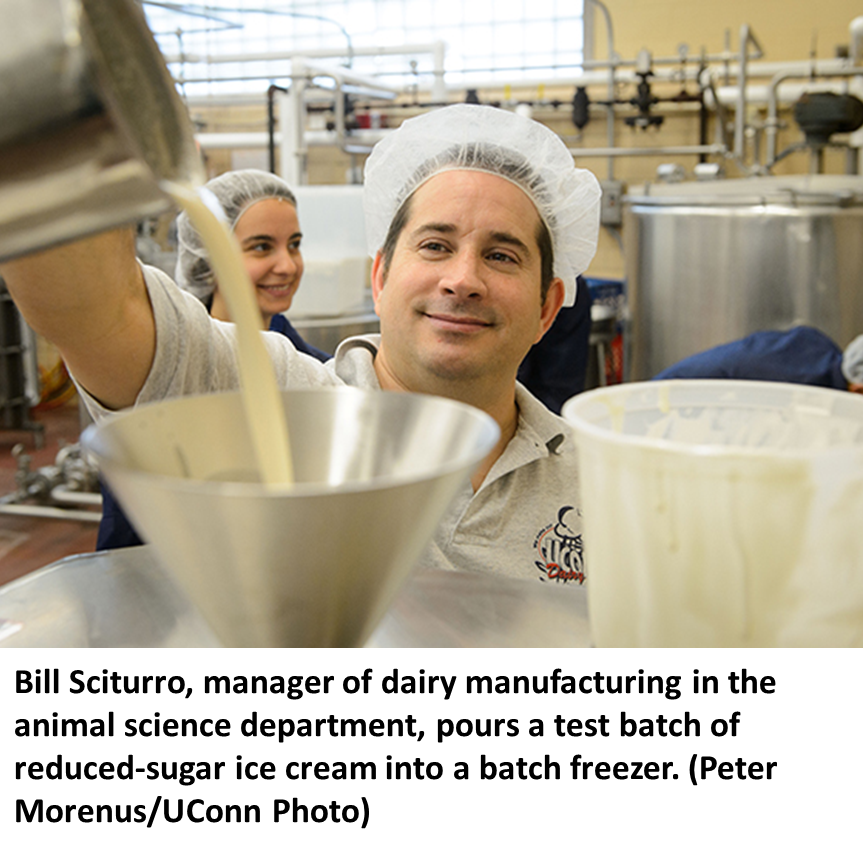

What happens when you mix UConn’s renowned Creamery and its top-notch Chemical Engineering department? If things go right, you get an ice cream that forgoes traditional sugar, but still earns a place along with the famously delicious ice creams at the Dairy Bar. One of the teams met on a recent morning at the UConn Department of Animal Science Creamery in the George White Building. This is where UConn’s ice cream is produced and later sold at the Dairy Bar next door. Bill Sciturro, manager of dairy manufacturing in the Department of Animal Science, helped the team work the batch machine, which freezes the mixture into ice cream. The aptly named machine makes one batch at a time – no more than a half gallon – and is used for testing purposes. Once a new recipe meets Creamery standards, it goes into production and is made with the continuous machine, which operates on a minimum of 50 gallons.

One of the teams met on a recent morning at the UConn Department of Animal Science Creamery in the George White Building. This is where UConn’s ice cream is produced and later sold at the Dairy Bar next door. Bill Sciturro, manager of dairy manufacturing in the Department of Animal Science, helped the team work the batch machine, which freezes the mixture into ice cream. The aptly named machine makes one batch at a time – no more than a half gallon – and is used for testing purposes. Once a new recipe meets Creamery standards, it goes into production and is made with the continuous machine, which operates on a minimum of 50 gallons. Ice cream’s semi-solid state is the result of a fragile balance of ingredients, and it’s no easy trick to replace old-fashioned sugar and still get the rich taste and texture that makes the Creamery’s ice cream so popular.

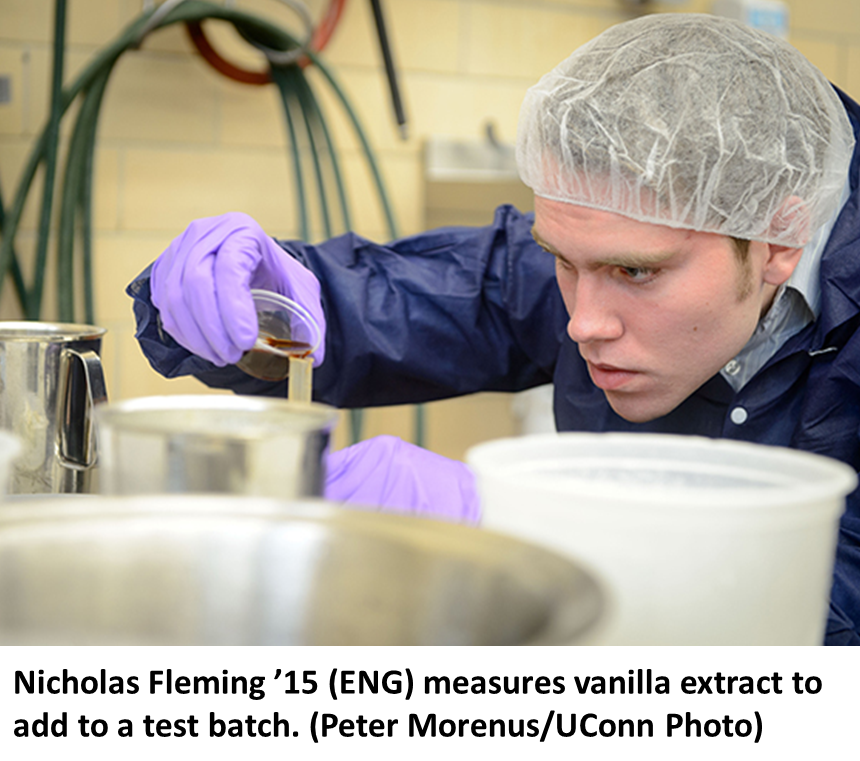

Ice cream’s semi-solid state is the result of a fragile balance of ingredients, and it’s no easy trick to replace old-fashioned sugar and still get the rich taste and texture that makes the Creamery’s ice cream so popular. After finishing the first batch at the Creamery, the team handed out samples to a few observers. Even at the very non-ice cream hour of 9 a.m., it proved a tasty snack – smooth, creamy, and betraying no indication of a non-traditional sweetener. At least to the casual observer. The team members were glad that the erythritol left no chemical hints or after-taste, but they agreed that the batch could use more vanilla. Team member Anh Nguyen said his ice cream palette has become a good deal more discriminating since the start of the project: “I’m a lot more picky.”

After finishing the first batch at the Creamery, the team handed out samples to a few observers. Even at the very non-ice cream hour of 9 a.m., it proved a tasty snack – smooth, creamy, and betraying no indication of a non-traditional sweetener. At least to the casual observer. The team members were glad that the erythritol left no chemical hints or after-taste, but they agreed that the batch could use more vanilla. Team member Anh Nguyen said his ice cream palette has become a good deal more discriminating since the start of the project: “I’m a lot more picky.”

Graduate student Christine Endicott is a true UConn Husky. Although a Vermont native, she received her B.S. in Chemical Engineering at UConn in 2008. Now, she’s back and in the second year of her PhD studies. And more? She’s still a Gampel season ticket holder.

Graduate student Christine Endicott is a true UConn Husky. Although a Vermont native, she received her B.S. in Chemical Engineering at UConn in 2008. Now, she’s back and in the second year of her PhD studies. And more? She’s still a Gampel season ticket holder. Dr. Yongku Cho, Assistant Professor in the Department of Chemical and Biomolecular Engineering, has received a prestigious and highly competitive

Dr. Yongku Cho, Assistant Professor in the Department of Chemical and Biomolecular Engineering, has received a prestigious and highly competitive  For the third consecutive summer, UConn’s Chemical & Biomolecular Engineering (CBE) Department hosed an NSF sponsored

For the third consecutive summer, UConn’s Chemical & Biomolecular Engineering (CBE) Department hosed an NSF sponsored  Instruments), High-Performance Nanostructured Organic/Inorganic Hybrids for Functional Applications (Nanocor), Development of Scalable Droplet Microfluidic Devices (BASF), Increasing Soil Water Retention with Bacteria (DuPont), Characterization of TiO2 Thin Films on 316L Stainless Steel Formed using a Sol-Gel Technique (VeruTEK Technologies), Plasmonic Nanodevices for Solar Energy Harvesting (Scitech Solar), and Sustainable Biofuels Production (RPM Sustainable Technologies).

Instruments), High-Performance Nanostructured Organic/Inorganic Hybrids for Functional Applications (Nanocor), Development of Scalable Droplet Microfluidic Devices (BASF), Increasing Soil Water Retention with Bacteria (DuPont), Characterization of TiO2 Thin Films on 316L Stainless Steel Formed using a Sol-Gel Technique (VeruTEK Technologies), Plasmonic Nanodevices for Solar Energy Harvesting (Scitech Solar), and Sustainable Biofuels Production (RPM Sustainable Technologies). Dr. Yu Lei, Associate Professor of Chemical and Biomolecular Engineering at the University of Connecticut, received a US Patent for his explosive detection technology.

Dr. Yu Lei, Associate Professor of Chemical and Biomolecular Engineering at the University of Connecticut, received a US Patent for his explosive detection technology.

The chemical engineering graduate program at the University of Connecticut is comprised of bright, innovative leaders who are motivated by change and challenge. The program offers the opportunity for students to enhance their skills and develop their potential.

The chemical engineering graduate program at the University of Connecticut is comprised of bright, innovative leaders who are motivated by change and challenge. The program offers the opportunity for students to enhance their skills and develop their potential. Dr. Nieh was recently awarded a National Science Foundation grant in 2012 to design such nano-carriers. “Lipid-based nanodiscs and vesicles have the potential to serve as delivery carriers for therapeutics or diagnostic agents, so the stability of the structure is an important issue,” he said.

Dr. Nieh was recently awarded a National Science Foundation grant in 2012 to design such nano-carriers. “Lipid-based nanodiscs and vesicles have the potential to serve as delivery carriers for therapeutics or diagnostic agents, so the stability of the structure is an important issue,” he said.